Polymer Drying

-

Industry:MaterialsHigh performance chemicalsPetrochemistry

-

Processes:Drying, concentration and dehydration

Social impact

An energy intensive process

One of the most important processes in polymer (plastic) production is “emulsion polymerization”. For example, super absorbent polymers (SAP), polyacrylic acid, polystyrene, and acrylic resin are often manufactured using emulsion polymerization. The emulsion polymerization uses water as medium therefore, before the product procession stage, polymer requires a thorough drying process. And this drying process uses a great amount of energy.

Results of Screening Tests

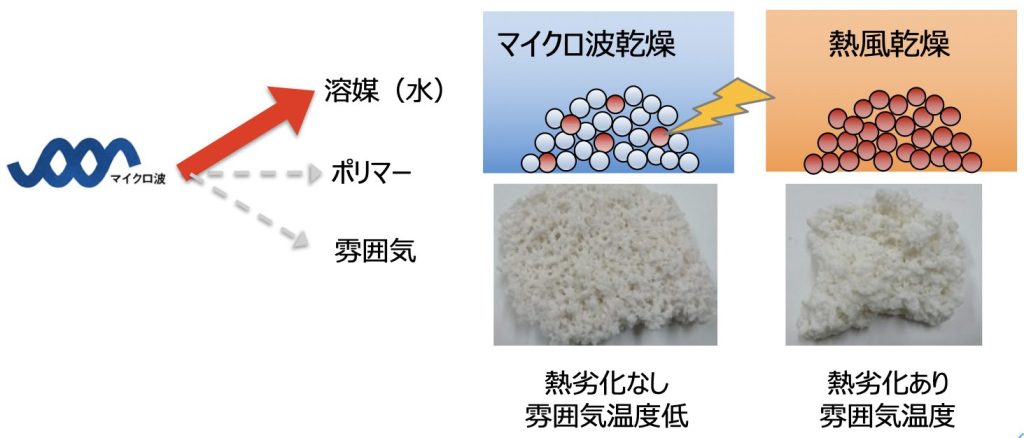

Microwaves do not heat plastics because they do not absorb microwaves very well; try reheating a plastic container in your microwave oven. Water, on the other hand, absorbs microwaves easily and heats up quickly. The reason why the contents of a plastic container are hot while the lid remains cool is because the microwaves selectively heat water.

This same principle can be applied to polymer drying. By selectively heating water, drying can be accomplished faster and with less energy compared to conventional drying methods that use hot air. There is also less thermal degradation because the polymers themselves are not heated, killing two birds with one stone.

Advantages of Using Microwaves

Microwaves do not heat plastics because they do not absorb microwaves very well; try reheating a plastic container in your microwave oven. Water, on the other hand, absorbs microwaves easily and heats up quickly. The reason why the contents of a plastic container are hot while the lid remains cool is because the microwaves selectively heat water.

This same principle can be applied to polymer drying. By selectively heating water, drying can be accomplished faster and with less energy compared to conventional drying methods that use hot air. There is also less thermal degradation because the polymers themselves are not heated, killing two birds with one stone.

| Moisture content chang | 60%→10% | 36%→10% |

| Conventional process (Hot air only) | 100 | 100 |

| MW process (MW + hot air) | 75 | 60 |

Future Prospects

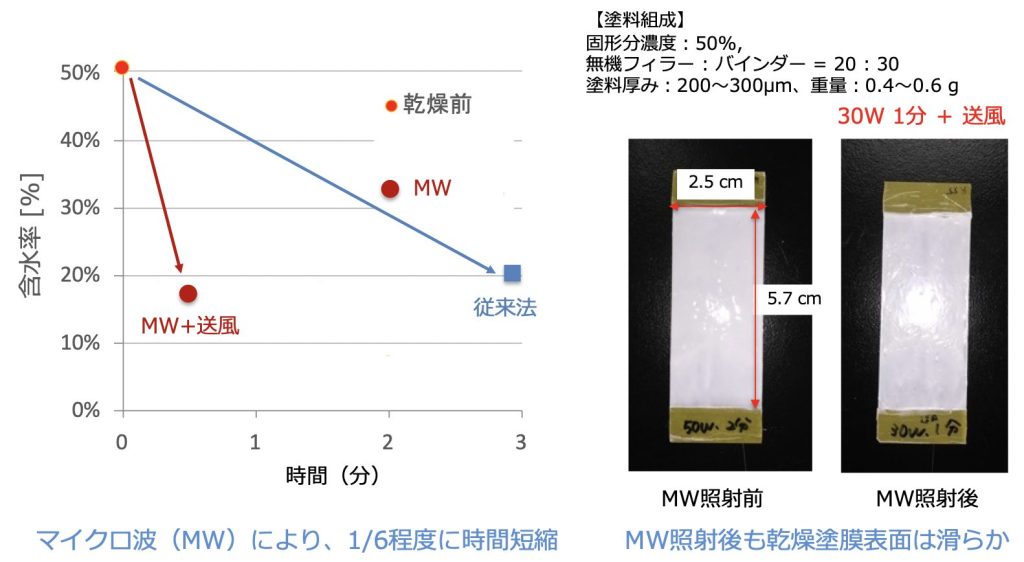

Drying of water-based paints

The principles behind drying polymers can be applied to other processes aside from post-polymerization water removal. For example, paints subject to volatile organic compound (VOC) emission regulations under the Air Pollution Control Act are required to switch from organic solvents to water-based equivalents. However, water has a higher boiling point (100°C) than organic solvents and even when compared to organic solvents with the same boiling point, water has a higher latent heat from vaporization, so the drying process will require more energy.

Switching to a microwave drying process will dramatically reduce drying time compared to conventional methods, which will lead to energy savings.

As the figure below shows, this result has been confirmed even for coatings with thicknesses in the μm range and we expect to deploy this method in more areas in the future.