Flow – 04

Bench and Pilot Validation

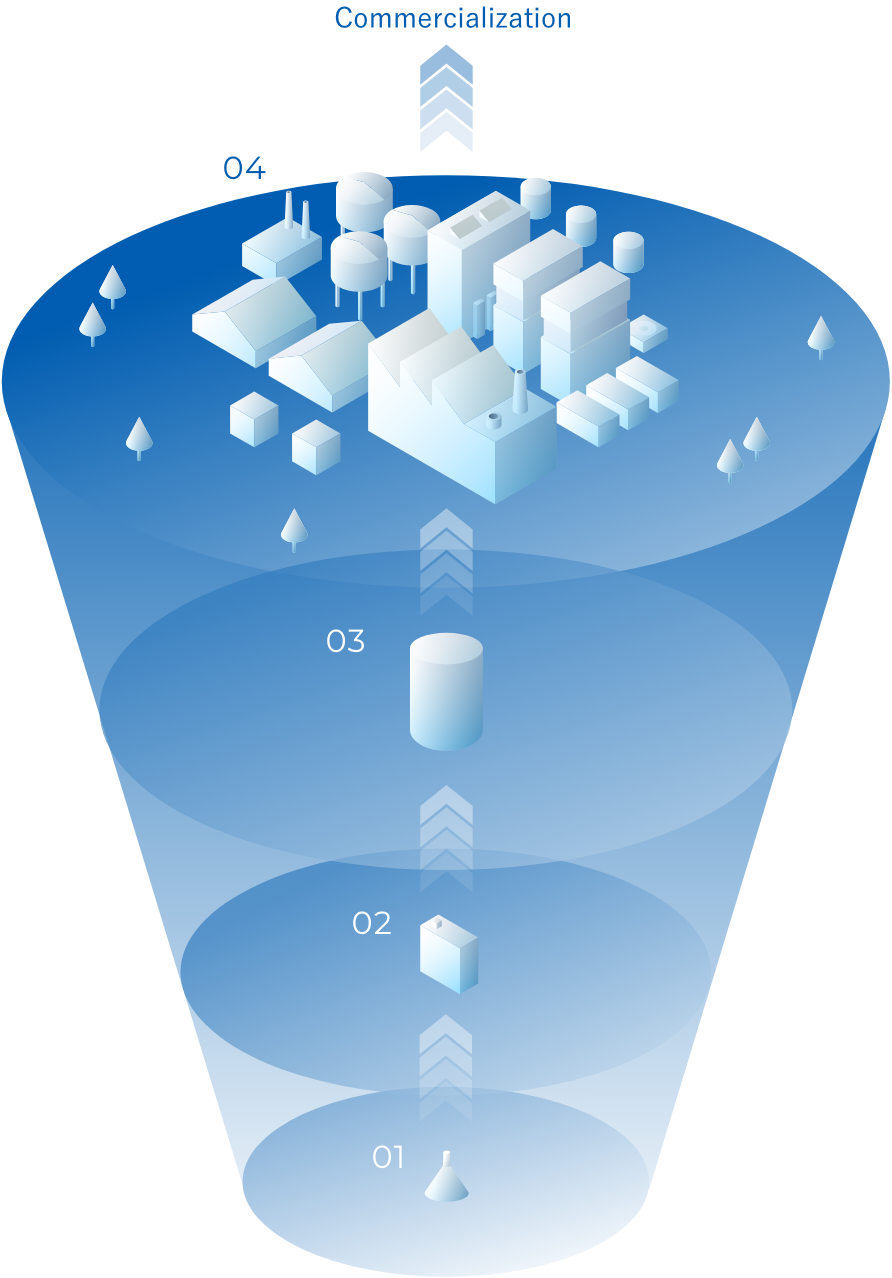

Our scale-up process consists of four steps: lab, bench, pilot and commercial-scale. We have already demonstrated the feasibility of the microwave process by operating an actual reactor with a production capacity of several tens of thousands of tons per year.

We use glass, fluorine, and stainless-steel materials for the microwave reactors in the lab, while we use vessels made of industrially viable materials in anticipation of scaling up for use in the actual plant for bench scale and onwards. The applicable temperature range is up to 2000°C based on actual results. In the low-temperature range, we are developing a microwave ice sublimation process under reduced pressure (a few Pa) at -40°C for microwave freeze-drying technology.

-

01Lab-scale5 – 500mL (flask level)

-

02Bench-scale5 – 50L (polyethylene tank level)

-

03Pilot-scale50 – 250L (drum level)

-

04Actual equipment500 – thousands of liters (factory level)

Microwave Reactor Shape

There are no restrictions on the shape of microwave reactors. Various reactor types are available and proven, including batch, kiln, conveyor belt, and continuous tank types.

- Batch type

- Kiln type

- Belt conveyor type

The following uses a stirred tank reactor as an example.

This reactor is a horizontal continuous tank type (overflow type) microwave reactor with an annual production capacity of approximately 3,000 tons.

waveguide that transmits the microwaves. The microwaves supply the vessels with the energy for chemical reactions and the material moves to the next layer by overflowing during the reaction. The microwaves are transmitted from the microwave generator to the waveguide and then to the unfilled space of the reactor.

The entrance and exit are open, so a structure to prevent microwave leakage such as a choke is required.

Start-up, Commissioning and After-sales Service, and Maintenance

Start-up, Commissioning

Whether the microwave reactor is at the bench, pilot, or commercial scale, a trial operation is conducted using water to ensure that there is no microwave leakage. If necessary, operation using actual liquids is also carried out. These procedures are standardized to ensure safe and smooth operation.

After-sales Service and Maintenance

After the equipment has been delivered, preventive and corrective maintenance are provided for after-sales service.

Preventive Maintenance

Periodic inspections and maintenance services are provided to ensure continuous and stable operation of the reactor. Inspections are carried out on a one-year or three-year cycle or based on operational hours.

Corrective maintenance

We investigate the cause of malfunction and lower performance of the machines and equipment by conducting temporary inspections or repairs. Every inspection includes checks on the condition of the microwave oscillators and their auxiliaries, reactor tests, sensor functionality assessments, and calibration. We also offer spare parts and provide replacement services for parts in need of replacement.