Freeze-drying

-

Industry:MaterialsFoodHigh performance chemicalsPharmaceutical

-

Processes:Drying, concentration and dehydration

Social Impact

Overturning the industry norm that freeze drying is time-consuming and expensive.

Freeze drying is a method of drying material in a frozen state (*sublimation, a phenomenon in which a solid directly converts to a gas) and is used in the manufacturing of various products, including pharmaceuticals and foods.

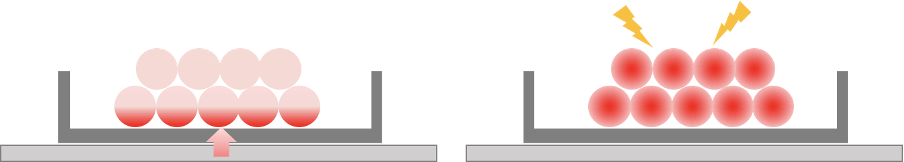

In conventional freeze drying, heat is transferred indirectly from the heated drying rack to the product on the rack. Relying on such an inefficient energy transfer method requires significant amount of time, anywhere from several days to as long as a week.

Heat-sensitive products must be freeze-dried at low temperatures, however, which is a widespread problem that contributes to higher manufacturing costs and reduced production capacity.

Results of Screening Tests

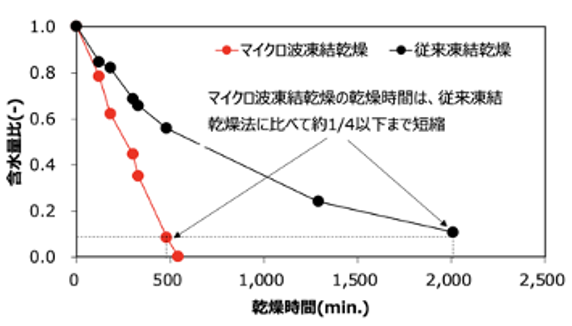

We created a freeze-drying apparatus that utilize the microwaves. We used this equipment to conduct a freeze-drying test on 500 g of 10% aqueous mannitol solution by irradiating PS waste plastic containing about 2% each of chlorine and bromine.

The results showed that drying time could be reduced to ¼ or below compared to conventional methods. The significant reduction in drying time also resulted in reduced degradation of product quality (flavor, etc.).

Advantages of Using Microwaves

Conventional two-dimensional heat transfer from a rack requires long drying time. However, by utilizing the microwaves, which can directly and selectively transfer energy to ice, we have succeeded in drastically shortening drying time.

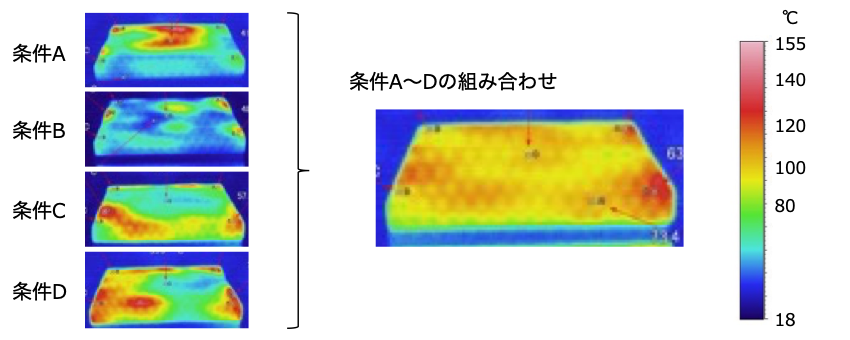

In addition, by utilizing element technology which we have developed in the past called the phase control (which controls the temporal and spatial distribution of microwaves), allows for the uniform drying of even static samples. This technology can now be used in the manufacturing of products such as vials filled with drugs, as well as instant/convenient food.

Future Prospects

Selling general-purpose equipment for food and pharmaceutical industries.

Long processing time and high costs have been persistent problems with freeze-drying, and we hope that our solution will help innovate freeze-drying. We have succeeded in developing universally applicable equipment and entered into the equipment sales business.