Service & Technology

Scale-up examples

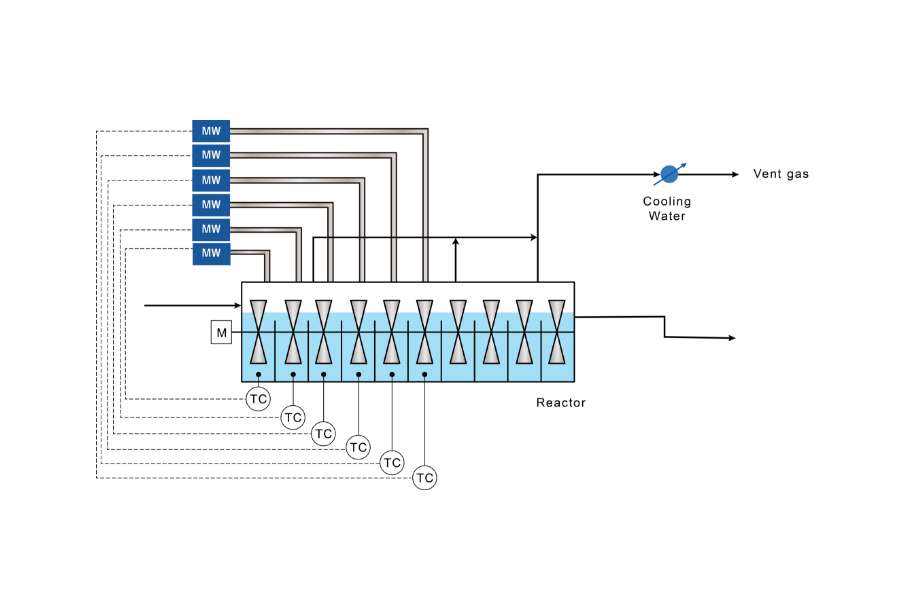

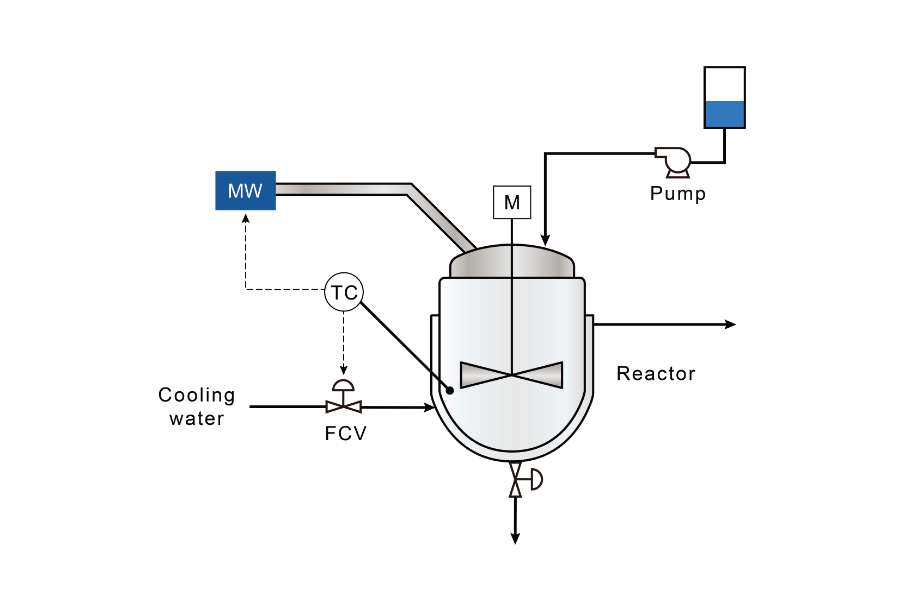

- Reaction system classification I Liquid system (normal pressure)

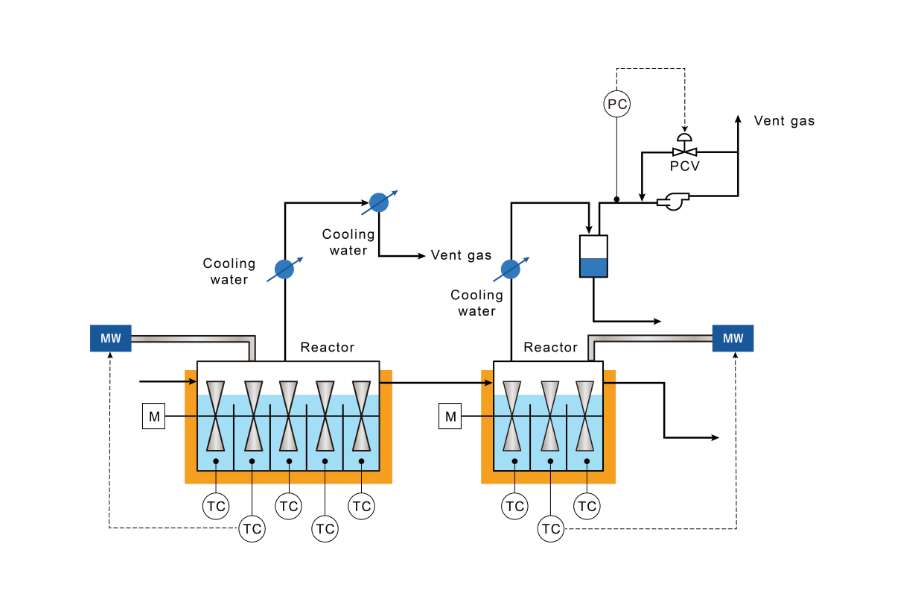

- Reaction system classification II liquid system (pressurized, reduced pressure, high temperature, high viscosity)

- Pharmaceutical synthesis (solid-phase synthesis)

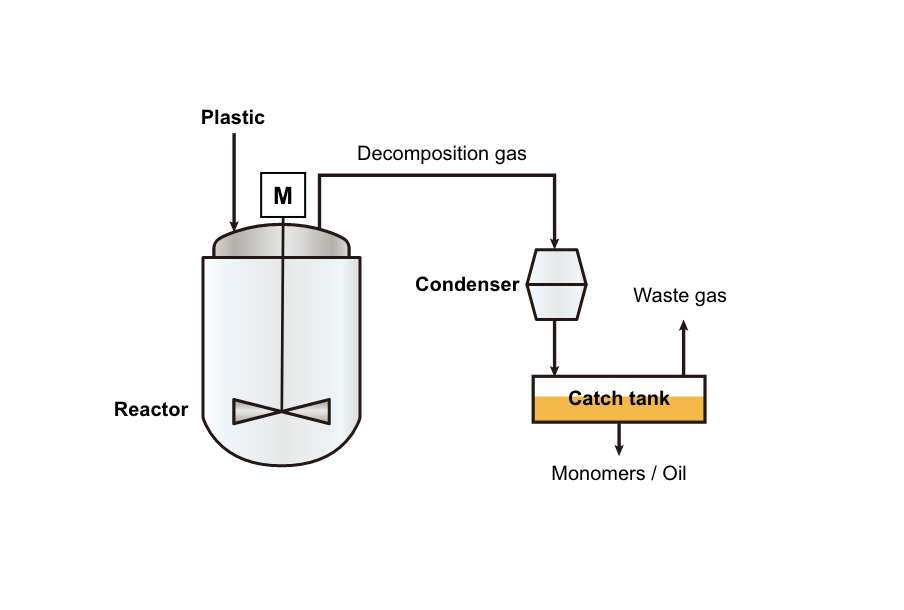

- Polymer pyrolysis/depolymerization

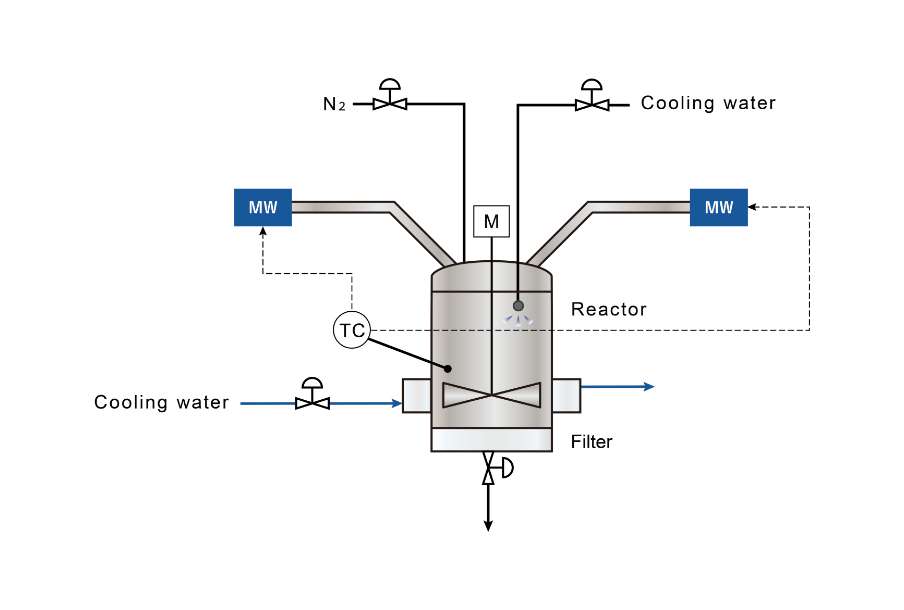

- Reaction system classification III Powder metal nanowires

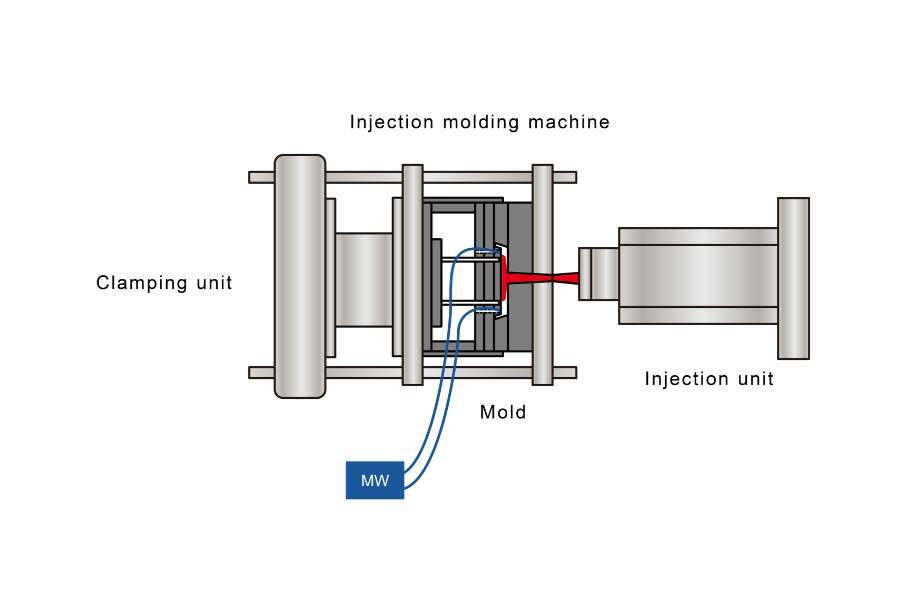

- Injection molding

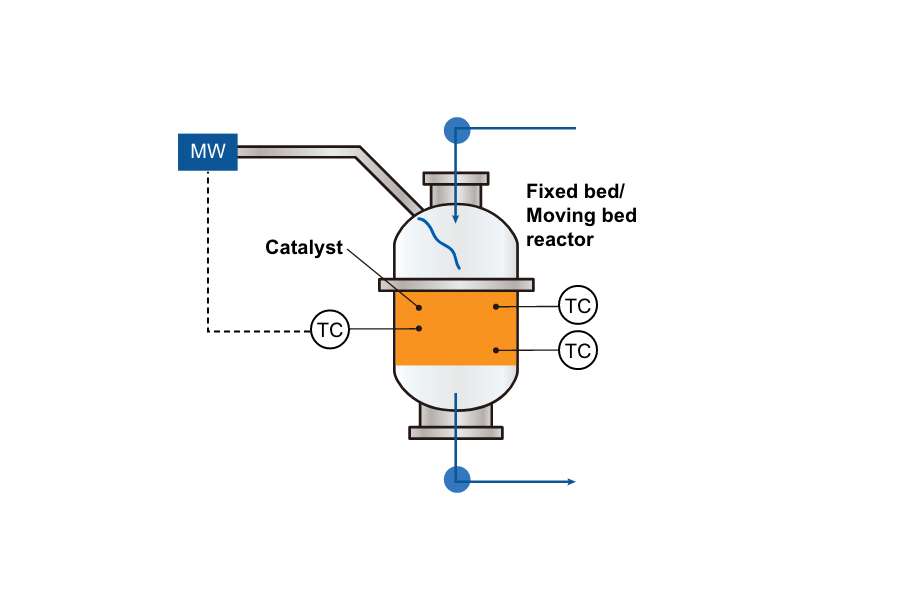

- Reaction system category IV Gas systems

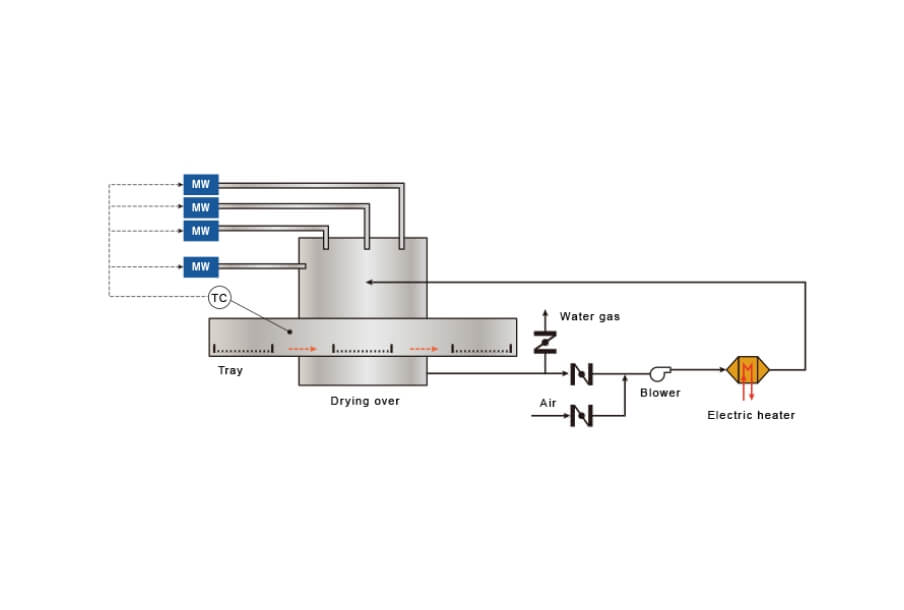

- Reaction system category V Drying/calcination drying

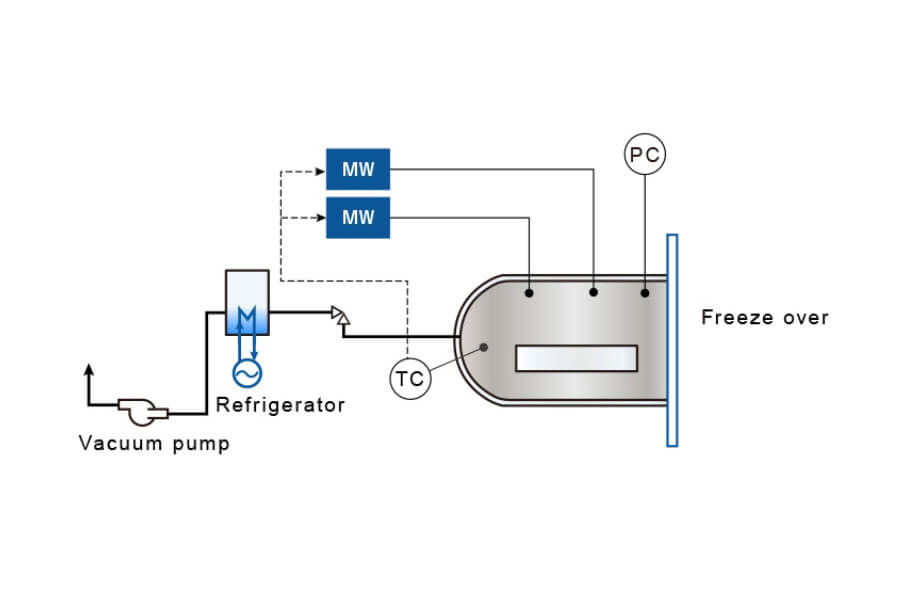

- Freeze-drying

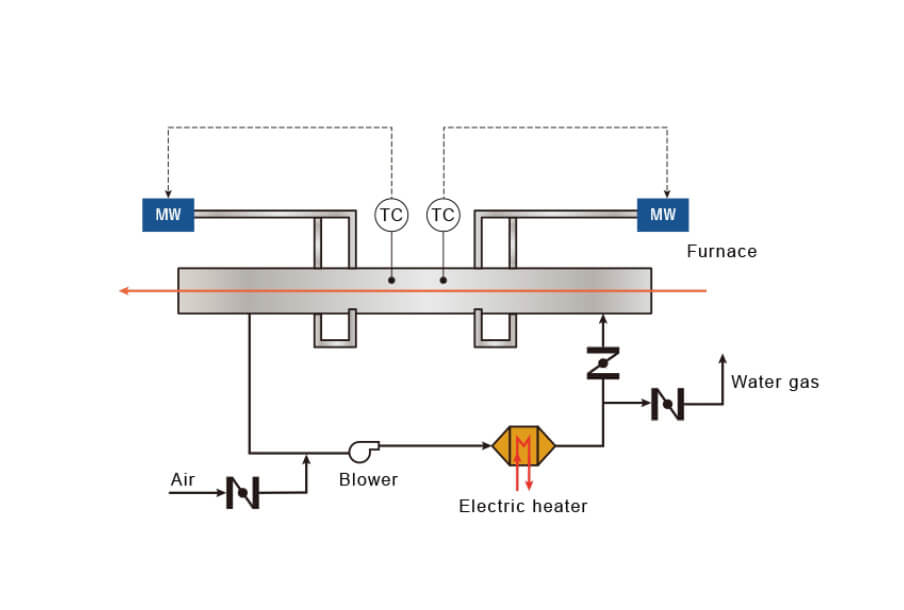

- Roll-to-roll

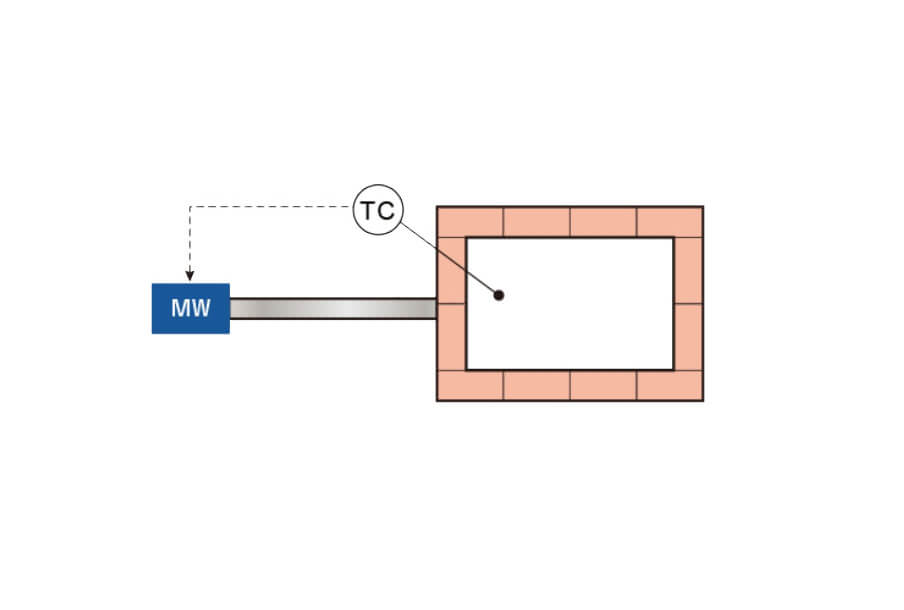

- calcination

| Reaction system classification | Process | Applications | |

|---|---|---|---|

| Ⅰ | Liquid (normal pressure) | Organic reactions | Ester reactions |

| Ⅱ | Liquid (pressurized, reduced pressure, high temperature, high viscosity) | Polymerization | Polymerization of polymers |

| Solid-phase synthesis | Pharmaceuticals (peptides, nucleic acids, etc.) | ||

| Polymer pyrolysis/ depolymerization | Chemical recycling of plastics | ||

| Ⅲ | Powder systems | Metal nanowires | silver nanowires |

| Injection molding, press molding | Plastic molding, thermoplastic composite molding | ||

| Ⅳ | Gas systems | Gas-solid catalytic reactions | Petrochemical systems |

| Ⅴ | Drying/calcination | Continuous drying | Food, chemicals |

| Freeze-drying | Food, pharmaceuticals, cosmetics, polymeric compounds, nanomaterials | ||

| Roll-to-roll | Drying and sintering of fibers/films | ||

| calcination | calcination of inorganic materials | ||