©︎ Microwave Chemical Co.,Ltd.

Get to know us in 3 minutes

What kind of a company is MWCC?

We want to enrich the world, by using the same technology used in microwave ovens to revolutionize the chemical industry.

In this section we give a simple introduction from our mission to our business model.

Mission

Just as the internet has modernized the world of communication and

electric vehicles have emerged as a new means of transport, we want to bring about

a major revolution in the chemical industry, upon which so much manufacturing is based.

The microwave-based technologies we have developed can not only revolutionize manufacturing processes,

but also contribute to carbon neutrality.

For a future that continues to develop, under beautiful skies,

with beautiful water and beautiful land.

To leverage businesses, technologies, and their impact on industry to create a new,

prosperous world beyond our wildest dreams.

To create worlds our world can’t even imagine.

The challenge to realize our mission has only just begun.

Vision

To reinvent a chemical industry which has remained unchanged for

over a century and transform the world of manufacturing.

To make microwave processing into a global standard.

The chemical industry is an important industry that keeps the world running,

by providing intermediate materials to manufacturers in a variety of fields,

from food and clothing through pharmaceuticals right up to aviation.

It accounts for about 30% of the entire industrial sector’s energy consumption,

and 17% of its CO₂ emissions. If we could create innovation to production processes

in the chemical industry, it would revolutionize how goods are manufactured around the globe.

Here at MWCC, we have developed unique technologies based on the same microwaves

that are used in microwave ovens. And our dream is to reinvent the world of

manufacturing by spreading these microwave processes not just in Japan but also globally.

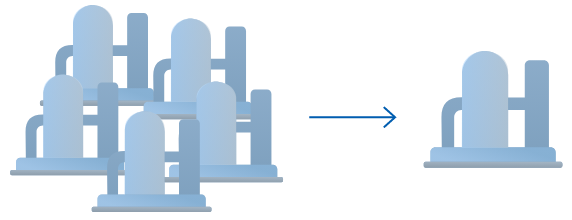

Chemical factories at the time of the 1900 Paris Exposition (image courtesy of BASF Corporate History)

A current chemical factory

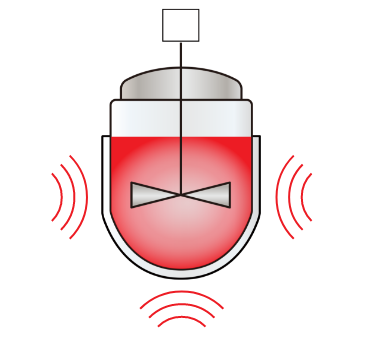

ColumnWhat is microwave?

Transmitting energy ‘directly’ from ‘within’, to ‘specific target materials.

In conventional manufacturing processes, energy is transferred ‘indirectly’, ‘from outside’, to everything. Microwaves, on the other hand transmit energy directly from ‘within’, only to specific target molecules s- in that sense, it is a complete opposite energy transmission compared to the conventional method.

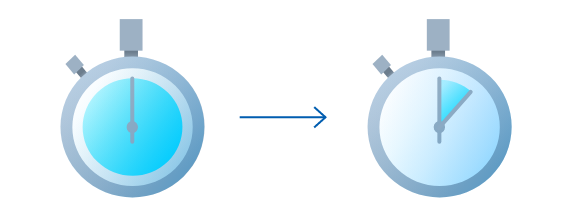

Conventional method

- Heat is transferred to everything, as the target cannot be specified.

- Heat is transferred indirectly, from outside, so it takes time for the overall temperature to rise. Consequently, the heat does not spread evenly, and the results are patchy.

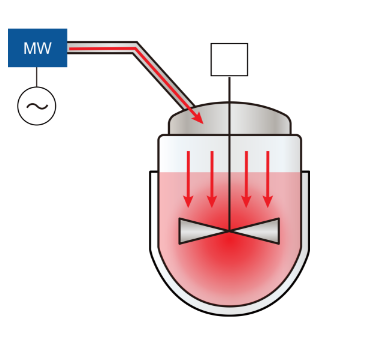

Microwave method

- Energy is transferred to specific targets at the molecular level.

- Heat is transferred directly, from within, which allows rapid heating and prevents uneven temperatures.

We can exploit this characteristic to achieve a quicker and more even rise in temperature while saving energy. Microwave technologies can benefit the entire chemical industry: not only heating, but also drying processes.

Strength

Changing manufacturing processes to create

new materials and contribute to carbon neutrality.

Innovations brought about by our microwave processes include:

-

Impact on

Process

New manufacturing processes

-

Impact on

Product

The development of new materials

-

Impact on

Carbon Neutral

Contributions to carbon neutrality through

electrification of the industrial sector

Impact on Process

New manufacturing processes

We achieve highly efficient and compact energy-saving manufacturing processes by applying energy directly to the target materials.

*Pilot test data from fatty acid ester production at our pilot plant. Actual figures will vary depending on the characteristics of the substance being produced.

-

Saving Energy

Energy consumption

1/3

Electricity consumption can be cut to 1/3 of that of conventional methods.

Energy consumption can be reduced to a fraction of that of conventional systems by inputting the energy primarily to the catalysts.

-

Higher efficiency

Heating time

1/10

Reactions can be made more efficient than conventional methods.

Using a hybrid catalyst which we developed with antenna-like functions, the catalyst interface can be put into a high-temperature, high-pressure state, giving a highly efficient process.

-

Compact

Ground area

1/5

Single-stage synthesis is now possible, instead of the conventional two stages.

Shorter reaction times allow for more compact equipment and a much smaller site area.

Impact on Product

The development of new materials

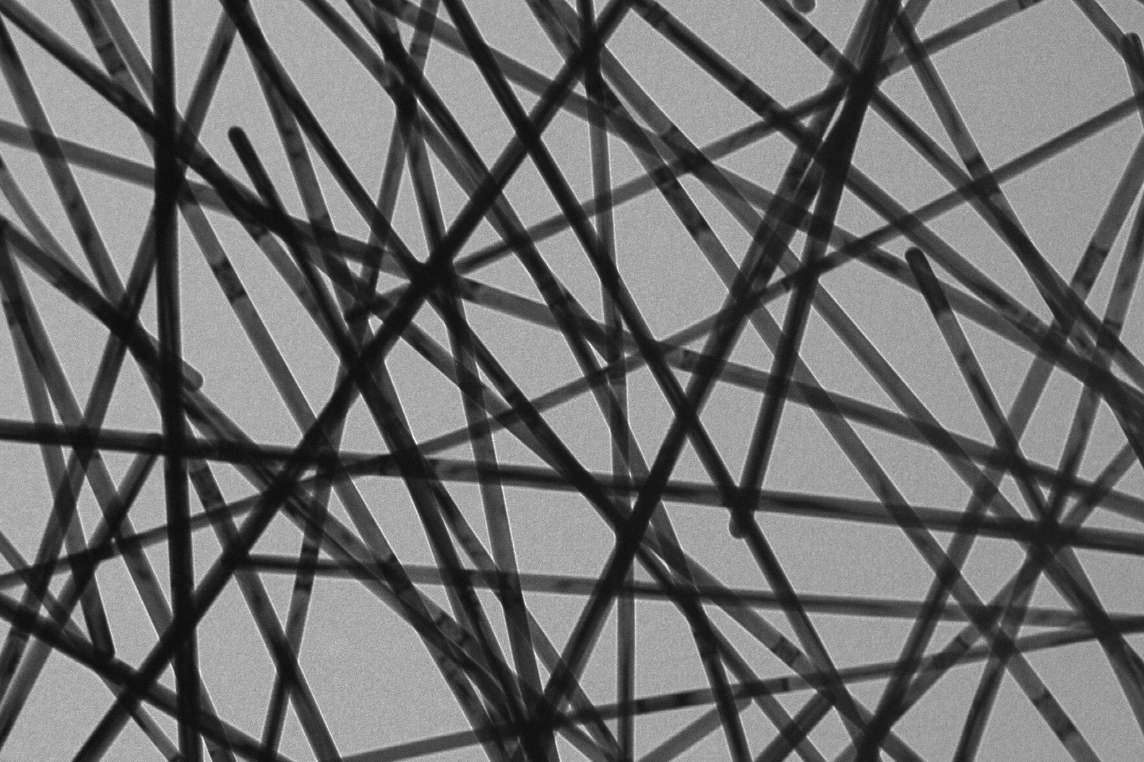

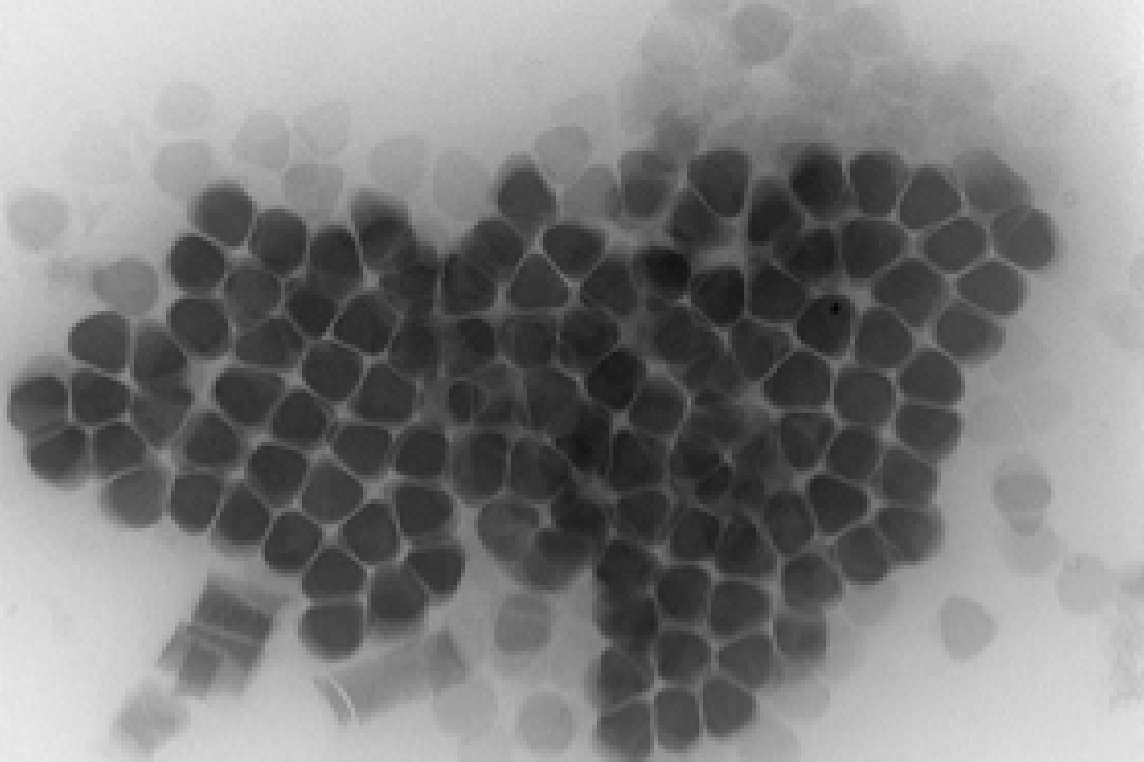

We can develop novel, high-quality materials whose manufacturing was previously not possible.

Silver nanowires

Nanoparticles

Impact on Carbon Neutral

Contributions to carbon neutrality through electrification of the industrial sector

Electrification based on renewable energy, combined with microwave processes, enables CO₂ emissions in the industrial sector to be significantly reduced.

CO₂ emissions reductions achieved

Organic synthesis

Firering or Baking

Pyrolysis

Energy equivalent reductions achieved

Organic synthesis

Firering or Baking

Pyrolysis

ColumnDesign

The key to scaling up microwave processes is our own unique technology.

People used to debate whether microwaves could truly be effective for manufacturing. At the time, industry generally believed that as microwaves are waves, they would be unable to penetrate deeply, they’d leak out easily, they’d reflect, or uneven distribution of the radio waves would result in patchy heating; hence there was a perception that it would be almost impossible to apply this technology on an industrial scale.

We poured a huge amount of time and effort into creating the following two designs that defied the convention.

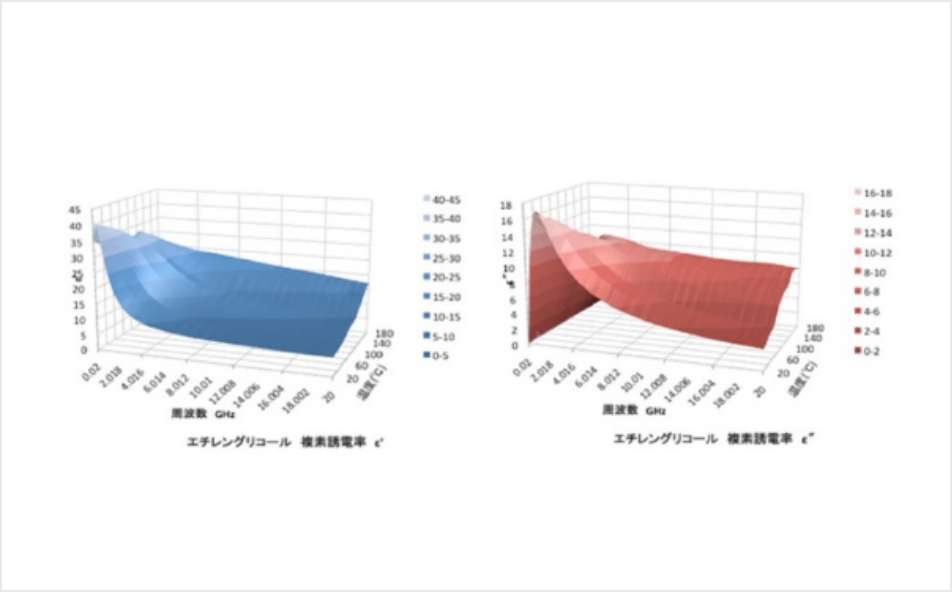

Reaction system design

We measure to what degree the substance to be reacted can absorb microwaves, and then select the optimum reaction conditions (frequency & temperature) from our vast library.

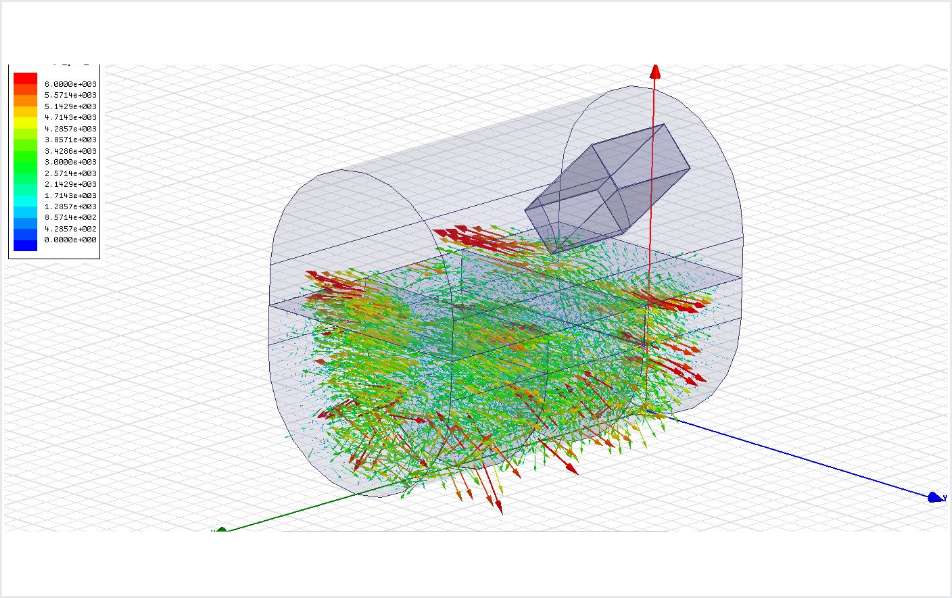

Reactor design

We use our engineering expertise and unique simulations to check how best to apply the microwaves, and then develop equipment that is both safe and efficient.

Business

We offer comprehensive solutions, from our first meeting

with a customer through to product commercialization.

As shown by the flowchart below, a feature of our business model is the way we provide a total solution, from meeting the customers who will become our co-development partners, through planning and trialing the development concepts, to commercialization, where we deliver operational systems and commercial facilities. It takes on average five years to commercialize a given project. Currently, a number of projects are ongoing in parallel.

Technology Platform

Future

Our vision of the future

Creating new value through collaborative work

with a range of companies.

MWCC is currently working with companies in and outside Japan to get several joint projects off the ground, based on our unique technologies and know-how. The technologies and materials we develop are expected to be exploited in a wide range of products. At the same time, using renewable energy will significantly reduce our CO₂ emissions. Our microwaves will electrify manufacturing, revolutionize production processes in the chemical industry, and reinvent the ways of manufacturing in the world.

Next contents