©︎ Microwave Chemical Co.,Ltd.

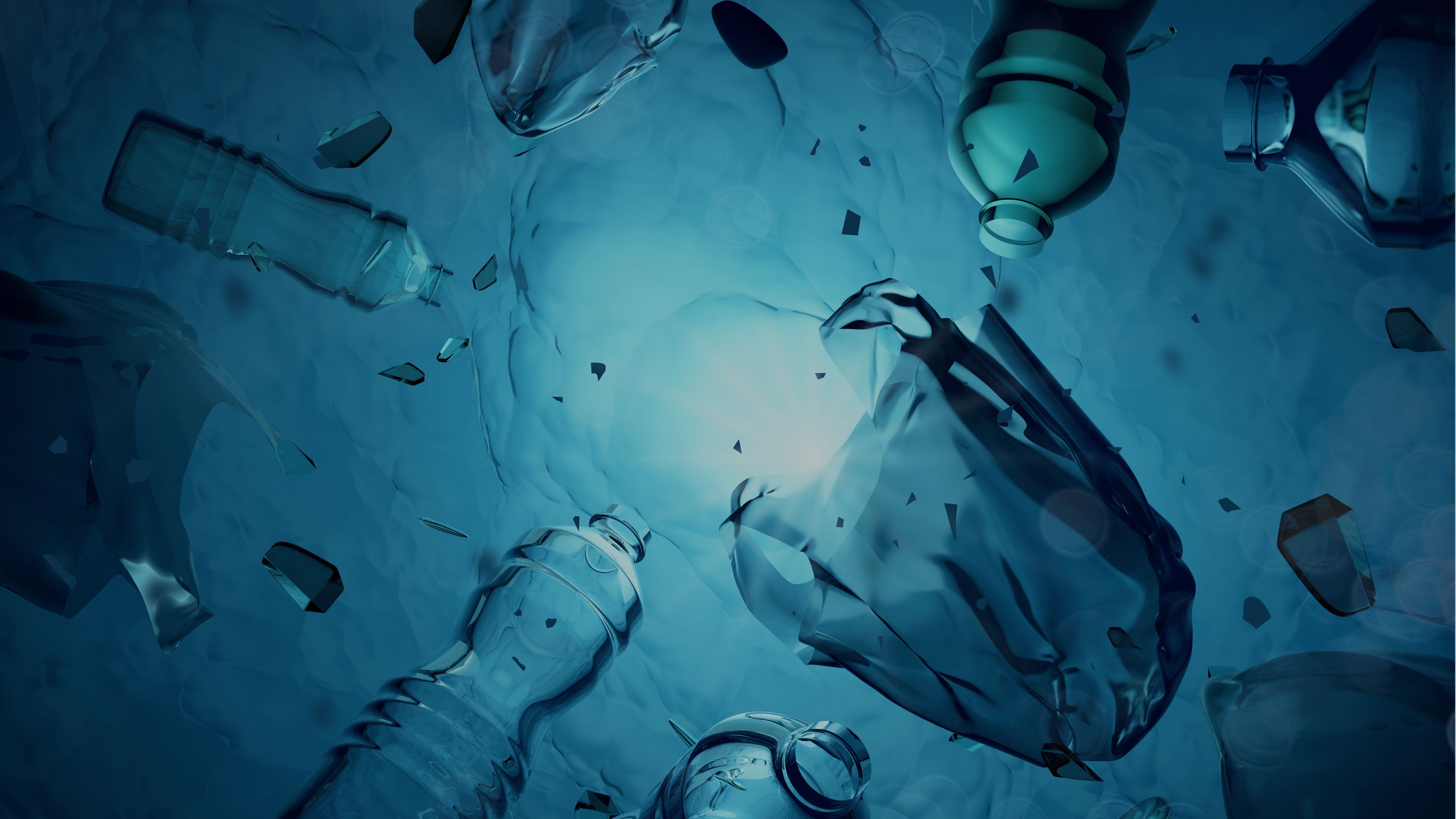

We combine a large-scale centlized system

and a small-scale distributed system

to establish an optimal recycling model.

We have reached the conclusion that it is necessary to realize both a centralized model, which processes a large volume of waste plastic in one location, and a distributed model, which processes relatively smaller amounts locally. Combining these two approaches, we will be able to construct an optimal system that contributes to the realization of a circular economy.

New Technology Utilizing Microwaves

PlaWave® enables highly efficient chemical recycling.

PlaWave®, a new technology utilizing microwaves that can selectively provide energy to the desired substances, addresses various challenges in chemical recycling. As an environmentally friendly and highly efficient technology, it is undergoing extensive validation with diverse plastics and starting to make progress towards societal implementation.

High Selectivity

By selecting a decomposition process tailored to the target decomposition products, high purity and yields can be achieved.

High Efficiency

The direct and rapid energy transfer, which is a feature of microwave technology, realizes energy-effecient chemical recyclying processes.

Space Saving

Combining high-speed processing using microwaves with compact utility facilities contributes to space-saving.