Electrification Platform for metal smelting (Green Mining-MX)

-

Industry:SmeltingEnvironmentMining

-

Processes:Calcination

Industry hurdles we face

New electrification platform for smelting and refining technology using microwaves “Green mining-mx”

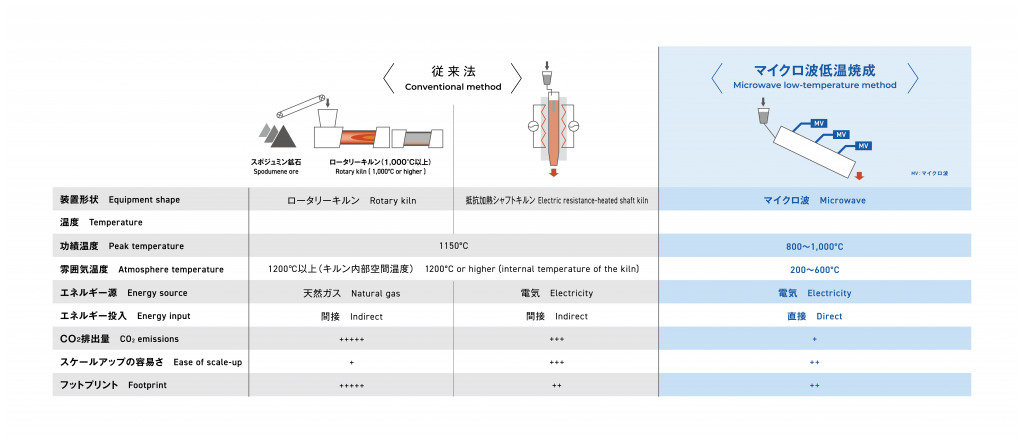

In metal smelting, ores are calculated in a high-temperature zone of 500°C or higher in the calcination and roasting processes.

The smelting industry heavily relies on fossil fuels, making it energy-inefficient. Consequently, cutting CO2 emissions is a significant hurdle in its path to achieving carbon neutrality.

Moreover, the smelting of certain nonferrous metals is concentrated in specific countries, such as China. For economic security reasons, it’s imperative to promptly establish a diversified supply network.

By using microwaves to enhance the efficiency of the smelting process and drastically reduce CO2 emissions, we aim to boost economic security.

Currently, we are conducting calcination tests on various ores using our self-developed standard bench machine “Green Mining-MxB”.

Why our technology matters

Combined with highly efficient and renewable energy sources, the smelting process can significantly reduce CO2 emissions and contribute to the promotion of economic security.

Future Prospects

Realization of decarbonization and economic security through electrification of mining processes

For lithium, we are currently developing this technology with the aim of commercializing it in 2026 and installing facilities in lithium mines and resource producers in Australia, Canada, and other countries. We are also working diligently to expand the scope of application to other ores and to develop the technology for social implementation by 2026.