2023.12.13 PRESS RELEASE

Successful Lab-Scale Reduction of Iron Ore with Microwaves 〜Contributes to Carbon Neutrality in Steel Production, a Significant Challenge in the Steel Industry〜

Microwave Chemical Co., Ltd.

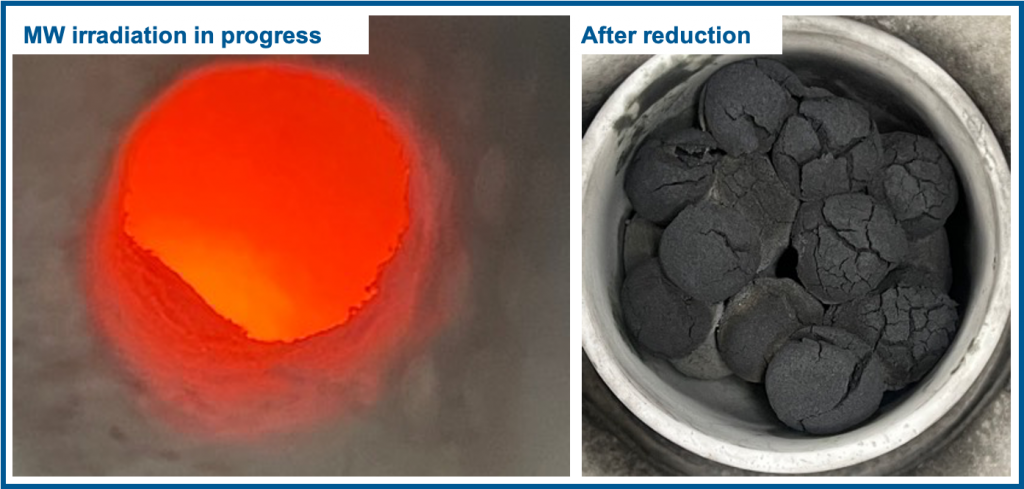

Microwave Chemistry Co., Ltd. (Headquarters: Suita City, Osaka Prefecture, CEO: Iwao Yoshino, hereinafter referred to as “MWCC”) has successfully reduced iron ore to iron using microwaves on a lab scale. We will continue to establish this technology and seek business partners for future endeavors.

The steel industry accounts for about 10% of global CO2 emissions, approximately 35% of industrial emissions in Japan, and about 12% of the country’s total emissions (as of fiscal year 2020)※1. Steel production methods typically involve reducing and melting iron ore and coal (coke) in blast furnaces and converters, or melting scrap iron in electric furnaces. The blast furnace method, in particular, inevitably emits a large amount of CO2 during the coal reduction process, significantly contributing to environmental impact. Therefore, a fundamental shift in the steelmaking process is essential to achieve carbon neutrality in the steel industry.

Scaling up the microwave reduction of iron ore has been a challenge. MWCC has recently achieved success in reducing iron ore to iron on a lab scale by utilizing our “Green Mining-MX” microwave technology platform, which is designed for various mining process developments. We are accelerating our development efforts towards commercialization. Iron ore and coal, used as a reducing agent, readily absorb microwaves, allowing direct heating and reducing energy consumption and CO2 emissions. This technology can also be applied to reduction processes using hydrogen or biomass, contributing to carbon neutrality in the steel industry.

Aiming for practical application, we plan to conduct demonstration tests using our standard bench-scale equipment by 2025 to establish the technology, and we are seeking partner companies for future business development. We also plan to apply this technology to upstream processes in steel production, such as the pelletizing process※2 of iron ore, contributing to reduced environmental impact across the steel industry.

MWCC will continue to work towards achieving carbon neutrality in the steel industry, leveraging our expertise in development of microwave technology in other fields.

※1 For more information, please refer to the following websites

IEA “Emissions Measurement and Data Collection for a Net Zero Steel Industry Executive summary”

https://www.iea.org/reports/emissions-measurement-and-data-collection-for-a-net-zero-steel-industry/executive-summary

Ministry of Economy, Trade and Industry, Agency for Natural Resources and Energy, “Global Efforts towards Decarbonization of the Steel Industry (Part 1) – What is ‘Green Steel’?”

https://www.enecho.meti.go.jp/about/special/johoteikyo/green_steel_01.html

※2 Pelletizing Process

A preparatory process for certain iron ores before they are fed into a blast furnace. This process involves mixing fine ore with substances like limestone or dolomite and forming them into spherical pellets of about 10-15 millimeters in diameter, which are then hardened by high-temperature baking.