Cracking(M-Cracker)

-

Industry:EnvironmentPetrochemistry

-

Processes:Gas-solid Reaction

Social Impact

Carbon Neutrality at the Source of Chemistry

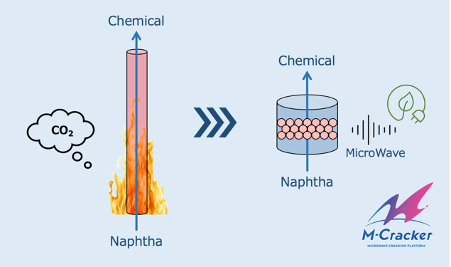

Currently, the petrochemical industry in Japan emits 60.18 million tons of CO2 annually, 51.5% of which comes from ethylene plants. Ethylene plants, which are the source of the petrochemical industry, use fossil fuels for the pyrolysis of naphtha cracking, and the CO2 emitted from these plants is one of the challenges in achieving carbon neutrality. Therefore, the development of fuel conversion to hydrogen and ammonia, which do not emit CO2, and conversion to electrification processes are currently underway.

The “M-Cracker®︎” converts the energy source of naphtha cracking technology, a basic chemical production process, to microwave heating. The M-Cracker converts the energy source of naphtha cracking technology, a basic chemical production process, to microwave heating, thereby directly heating the reaction field, which is a characteristic of microwave processes, and thus represents a new concept of cracking process different from conventional methods.

Advantages of Using Microwaves

By converting to the microwave process and utilizing renewable energy, CO2 emissions can be reduced by 90% compared to existing processes.

Furthermore, the realization of direct heating will suppress coking(carbon deposition caused by free radical carbons), which has been a problem in the operation of naphtha cracking, and will enhance the competitiveness of ethylene plants.

Future Prospects

Further Advancement and Establishment of Technology for Social Implementation

We aim to further advance the developed technology by combining it with naphtha catalytic cracking technology.

We will establish the basic technology, conduct continuous operation verification, and strive to implement the technology in society.