Numerical Simulation Technology for Microwave Reactor Design: Practical Applications and Latest Trends in Electromagnetic Field, Thermal-Fluid, and Multiphysics Simulation

Microwave heating is finding applications in a wide range of fields, including communications, medicine, materials science, and chemical engineering. In reaction engineering, its use as an energy transfer method is gaining particular attention. Unlike conventional heating technologies, microwaves generate heat directly within a material through electromagnetic waves, enabling process control with excellent high‐speed response and selective heating capabilities [1].

To leverage these characteristics on an industrial scale, a detailed understanding of the electromagnetic field, thermal, and fluid distributions is essential for equipment design. At the core of this process is “numerical simulation.” This article provides a detailed explanation of the technical fundamentals and application examples of “Electromagnetic Field Analysis,” “Computational Fluid Dynamics,” and “Multiphysics Simulation,” which integrates them, all of which are crucial for the design and optimization of a microwave reactor. We will also explore cutting-edge trends involving AI and cloud technologies.

What Is a Microwave Reactor?

Mechanism and Features of Microwave Heating

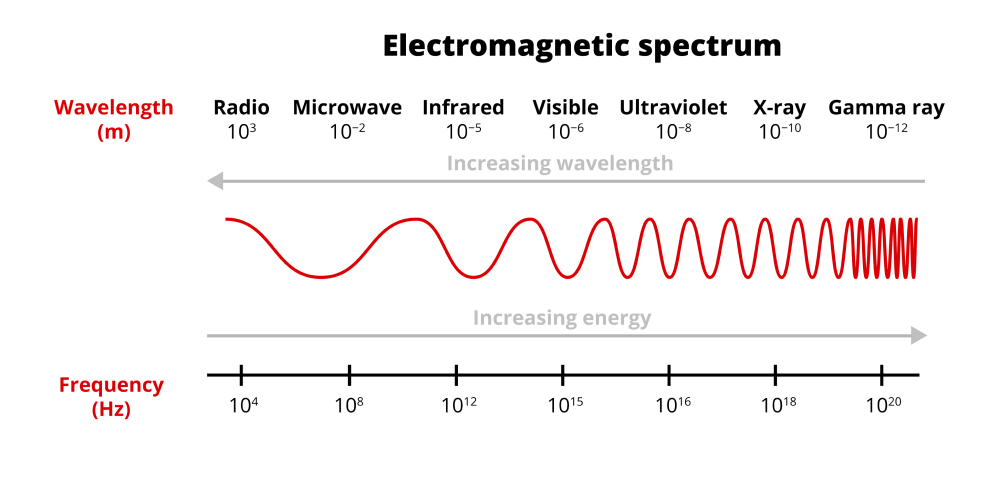

Microwaves are the radio frequency (RF) electromagnetic waves with frequencies ranging from 300 MHz to 300 GHz (wavelengths from 1 m to 1 mm). For industrial applications, the 2.45 GHz (wavelength approx. 12.2 cm) ISM band is predominantly used. The most significant feature of microwave heating is its ability to perform “volumetric heating,” which generates heat directly inside a substance. While this unique internal heating is powerful, it also presents challenges for industrialization, making advanced design tools such as numerical simulation indispensable.

Internal heating is achieved as microwaves interact with materials, resulting in energy dissipation (i.e., thermal generation). The primary heating mechanisms are classified into the following three types, with the dominant loss mechanism varying depending on the material’s properties.

(1) Dielectric Heating

Polar molecules and ions rotate and vibrate in response to the electric‐field component (E), generating heat through frictional loss.

- Primary Targets: Water, ethanol, saline solutions, organic solvents, etc.

- Dominant Material Properties: Complex permittivity ε = ε′ − jε″

- Indicator: Dielectric loss tangent tan δ = ε″ / ε′

- Characteristics: The most common form of microwave heating. Highly efficient for substances with strong polarity.

(2) Magnetic Loss Heating

Magnetic materials respond to the magnetic‐field component (H), causing their magnetization vectors to reverse, which generates heat from hysteresis and relaxation losses.

- Primary Targets: Ferrites, metal oxides (e.g., Fe₃O₄), magnetic nanoparticles

- Dominant Material Properties: Complex permeability μ = μ′ − jμ″

- Indicator: Magnetic loss tangent tan δₘ = μ″ / μ′

- Characteristics: Enables heating of non-metallic materials. Applied in nanomaterials and medical hyperthermia.

(3) Conductive Loss / Joule Heating

Eddy currents are induced in conductive materials, and heat is generated as resistive loss (I²R) from the current flow.

- Primary Targets: Graphite, metal powders, carbon nanotubes

- Dominant Material Properties: Electrical conductivity σ or the conductive term contribution to permittivity (ε″ ∝ σ/ω)

- Characteristics: Extremely strong heating is possible in highly conductive materials, but there is a risk of overheating and electrical discharge.

In actual microwave reaction systems, these heating mechanisms often act in combination rather than in isolation. Therefore, to maximize heating efficiency, it is essential to accurately evaluate the ε″, μ″, and σ of the target material and predict the dominant loss mechanism during the design phase.

Basic Configuration and Variations of Microwave Reactors

A typical microwave reactor consists of the following components:

| Component | Role |

|---|---|

| Microwave Source (Magnetron, Solid-State Amplifier) | Generates microwaves at frequencies like 2.45 GHz. |

| Waveguide / Impedance Matching | Efficiently guides microwaves into the reaction space. |

| Reaction Vessel (Cavity) | Contains the material to be heated. Dielectric properties are a key consideration. |

| Stirring Mechanism | Promotes substance mixing and temperature uniformity. |

| Temperature Sensor & Control System | Achieves heating control using methods like PID control. |

| Shielded Enclosure Leakage Detector System | Ensures safety from leaked electromagnetic waves. |

Furthermore, there are several design variations:

- Single-Mode vs. Multi-Mode Resonators: Single-mode is suitable for localized heating, while multi-mode is better for improving heating uniformity.

- Continuous vs. Batch Type: Selected based on production throughput and process control requirements.

- Antenna-Based Irradiation: In medical and environmental fields, open-system irradiation is also applied.

Examples of Dielectric and Magnetic Properties Affecting Heating Efficiency (Typical Values in the Microwave Band)

| Substance | ε′ (Permittivity) | tan δ (Dielectric Loss) | μ′ (Permeability) | tan δₘ (Magnetic Loss) | Heating Performance |

|---|---|---|---|---|---|

| Water (20°C) | Approx. 78 | 0.12 | ≈1 | Almost zero | Very good |

| Graphite | Hard to define | High (due to conductivity) | ≈1 | Negligible | Extremely good |

| Fe₃O₄ | 10–20 | 0.1–0.3 | 2–6 | High (>0.5) | Good (due to combined losses) |

| Polypropylene | 2.2 | 0.0002 | ≈1 | Negligible | Almost no heating |

As shown, understanding the electromagnetic response of each material can dramatically improve the heating efficiency, temperature controllability, and selectivity of a reactor design [3].

Why Numerical Simulation is Crucial for Microwave Reactor Design

The performance of a microwave reactor cannot be optimized simply by irradiating microwaves. Multiple independent factors—such as the reactor’s shape, feeding method, sample position and volume, vessel material, and even material properties that change during the reaction (e.g., temperature-dependent permittivity)—intricately affect the propagation, absorption, and reflection behavior of microwaves.

To control such non-intuitive and strongly coupled design parameters, the use of numerical simulation is indispensable. Traditional prototype-based design methods often face challenges like uneven heating, resonance point shifts, and microwave leakage, which increase development costs and time. Numerical simulation is a vital tool that helps visualize and predict these issues in the early design stages, supporting efficient development. The main advantages are as follows:

(1) Early detection and Elimination of Uneven Heating and Hot Spots

In microwave heating, electromagnetic wave interference can create localized high-electric-field regions (hot spots) and nodes (unheated areas) within the reaction field. These can compromise reaction selectivity and reproducibility. By visualizing the electric and magnetic field distributions through electromagnetic field analysis, it is possible to identify the risk of hot spots at the design stage and optimize the sample placement and cavity structure [1].

(2) Reduction of Prototyping Cycles and Development Costs

Development based on conventional empirical rules requires numerous man-hours for the cycle of prototyping, evaluation, and improvement. By using numerical analysis to predict parameters like the reflection coefficient (S₁₁), resonance frequency, heat generation distribution, and temperature gradients in advance, it is realistic to reduce the number of prototypes to one-third or less.

(3) Reliable Scale-up Performance

A design that performs well at the lab scale often fails to function after scale-up. This is because changes in cavity size and load conditions alter the interference pattern of electromagnetic waves, leading to significant changes in the heating distribution. Utilizing a microwave simulation model enables the redesign of the electromagnetic field analysis and thermal fields to accommodate scaling.

(4) Evaluation of Multiphysics Interactions (Electromagnetic + Thermal + Fluid + Reaction) Coupling

In microwave heating, changes in material properties due to temperature rise (especially permittivity) affect the electromagnetic field distribution, which in turn influences thermal-fluid behavior and reaction rates. To capture this, coupled simulations of electromagnetic field and Computational Fluid Dynamics are essential. Furthermore, by incorporating a reaction engineering model, it becomes possible to predict the spatial distribution of reactions and the localization of products [2].

(5) Early assessment of Safety and Microwave Leakage

For industrial applications, addressing safety risks from microwave leakage and electromagnetic interference (EMI) is mandatory. Numerical simulation allows for the prediction of electric field strength in gaps and joints, enabling the early identification of high-leakage-risk areas. It also helps evaluate the risk of localized arcing or sparking and assess the adequacy of shielding designs. This makes it possible to verify compliance with safety standards at the design stage, contributing to the reliability of product development.

Overview of Numerical Analysis Methods Commonly Used in Reactor Design

In microwave reactor design, various numerical analysis methods are employed depending on the physical phenomena being targeted and the required accuracy at each design stage. Here, we outline the primary analysis methods, their features, and representative microwave simulation software.

1) Electromagnetic Field Analysis

1. Finite Element Method (FEM)

- Features: Capable of high-precision calculations. It is well-suited for analyzing complex geometries because the mesh (discretized domains) can be finely controlled locally.

- Use Cases: Analysis of electromagnetic field (E-field, H-field) distribution, dielectric loss distribution, and cavity resonance modes.

- Representative Software: Ansys HFSS, COMSOL RF Module

FEM is strong in frequency-domain analysis and is suitable for calculating S-parameters and precisely evaluating cavity resonance frequencies. COMSOL, in particular, facilitates coupling with other physics (thermal, fluid, reaction), making it ideal for integrated design studies.

2. Finite-Difference Time-Domain (FDTD)

- Features: Accurately reproduces the propagation behavior of electromagnetic waves in the time domain, making it suitable for wide-band analysis and transient response analysis immediately after switch-on.

- Use Cases: Used in antenna design, EMI analysis, and radar absorber evaluation.

- Representative Software: CST Microwave Studio, OpenEMS

However, for systems like microwave reactors, which operate on a narrow band and in a steady state, the application of the FDTD method is relatively limited. In reactor design, where the steady-state distribution at a specific frequency is prioritized, frequency-domain analysis using FEM is generally superior in both efficiency and flexibility.

2) Computational Fluid Dynamics (CFD)

- Features: An indispensable method for quantitatively evaluating the physical heating process caused by microwaves. It is also closely related to reaction kinetics.

- Use Cases: Analysis of temperature distribution within the reactor, convection and diffusion phenomena, and cooling system design.

- Representative Software: ANSYS Fluent, COMSOL Heat Transfer/CFD Module

By utilizing CFD, it becomes possible to visualize non-uniformities caused by uneven heating and temperature gradients, enabling more realistic predictions of thermal behavior.

3) Multiphysics Simulation

- Features: Essential for a deep understanding of phenomena and optimal design, as it allows for the simultaneous evaluation of multiple different physical fields (e.g., electromagnetic and thermal fields) that influence each other.

- Example Combinations: Electromagnetic field + thermal field, electromagnetic field + fluid + chemical reaction.

- Representative Software: COMSOL Multiphysics, ANSYS Multiphysics

For instance, the heat generation distribution Q(x, y, z) obtained from electromagnetic field analysis can be used as a heat source for thermal analysis to determine the temperature distribution. Furthermore, the temperature rise affects the permittivity and loss factor, which in turn changes the electromagnetic field distribution. The ability to reproduce such bidirectional coupling effects is a major advantage.

4) Design Optimization & AI-Assisted Design

- Features: A method that uses AI and optimization algorithms to streamline design space exploration and automate sensitivity analysis in microwave reactor design.

- Use Cases: Automated design of waveguide/antenna shapes (minimizing reflection coefficient S₁₁), parameter sensitivity analysis, and design screening under complex conditions.

- Implementation Examples: modeFRONTIER (multi-objective design exploration and optimization), COMSOL Optimization Module

In recent years, for problems with high design freedom and many parameters, high-speed design space exploration combining machine learning has proven effective, and research into AI-assisted design methods is advancing.

Thus, the design of a microwave reactor requires both analysis methods to accurately capture diverse physical phenomena and the modeling skills to link them appropriately. The next chapter will focus on how these methods are utilized in the actual design process, with a particular emphasis on the application of electromagnetic field analysis.

Fundamentals of Electromagnetic Field Analysis (Principles and Parameters)

In microwave reactor design, electromagnetic field analysis is one of the most fundamental and critical methods. Based on Maxwell’s equations, it numerically predicts how microwaves propagate, reflect, and are absorbed in space and within materials, providing indispensable information for determining the reactor’s design elements.

Key Analysis Targets

- Electric Field (E) and Magnetic Field (H) Distribution: Evaluated to visualize the intensity and distribution of heating. This directly relates to the detection of localized hot spots and uneven heating, significantly impacting reaction selectivity and reproducibility.

- Electromagnetic Power Absorption Distribution (P_abs): Indicates the spatial power dissipation density (W/m³) resulting from dielectric, magnetic, and conductive losses. This is the very starting point of heating and is an essential indicator for temperature control and scale-up considerations in the reaction field.

- Resonance Characteristics and S-parameters (as needed): Used as supplementary indicators to evaluate the efficiency of matching units and feed structures. While not a direct evaluation of the reactor body’s performance, they are useful for optimizing the external feeding system.

These analysis results directly influence the shape design, sample placement, feed position, material selection, and electromagnetic shielding design of the reactor, and are therefore conducted in the early stages of development.

Why Electromagnetic Field Analysis is Essential for Microwave Reactor Design

In the design of chemical reactors using microwaves, it is critically important to know in advance “where heat is generated,” “how efficiently it can be heated,” and “whether microwaves are contained.” electromagnetic field analysis is the microwave simulation technique that allows for the quantitative visualization of these factors. For the following three reasons, introducing electromagnetic field analysis from the initial design stage is highly recommended.

1. To Accurately Predict Microwave Reflectivity and Absorption Distribution

When microwaves are introduced into a reactor, some of the energy is absorbed by the sample and internal structures, while the rest is reflected or transmitted. Understanding “where that energy turns into heat” determines the heating efficiency and reproducibility of the reactor.

Electromagnetic field analysis can quantify these behaviors in three dimensions using indicators such as:

- Reflection Coefficient (S₁₁): Represents the proportion of energy sent from the microwave source that is reflected back without entering the reactor. A high reflection coefficient not only reduces heating efficiency but also increases the risk of damage to oscillators like magnetrons. It is an essential evaluation metric for optimizing the matching design.

- Electromagnetic Power Absorption Distribution (P_abs ≈ ε″E² + μ″H²): Shows how microwave energy is converted into heat within the material. This allows for the pre-visualization of heating zones (hot spots) and uneven heating, which helps in controlling reaction selectivity and mitigating the risk of thermal runaway.

- Since a material’s permittivity and conductivity vary with temperature and moisture, a static design alone is insufficient. Electromagnetic field analysis enables the dynamic reflection of these changes, which are difficult to capture through experimental trial and error alone.

2. Identifying Optimal Design Parameters

To maximize the effects of microwave heating, it is necessary to precisely design “from where” and “how” microwaves are introduced and “how they are controlled internally.” By utilizing electromagnetic field analysis, the design of the following components can be evaluated numerically, without relying on intuition or prototyping:

- Feed Port Structure (Waveguide, Coaxial Feed, etc.)

The interface for introducing microwaves into the reactor. Simulation can help find the optimal position and structure for maximum efficiency.

- Material and Thickness of the Hermetic Window (Quartz, Ceramics, etc.)

It must strike a balance between microwave transparency and mechanical strength. For instance, minor differences in material or thickness can cause resonance or reflection, making it crucial to consider material selection and structural design in tandem.

- Microwave Propagation within the Reactor (Electric Field Distribution)

The electromagnetic field distribution can be adjusted using metal pin-like probes or spatial radiation-type feed structures. This allows for targeted design to concentrate heating in specific areas or achieve uniform heating.

- Optimization of Matching Structures to Suppress Reflection

To prevent microwaves from reflecting off the sample or vessel, the wave’s phase and energy density must be adjusted by designing the placement of dielectrics and the propagation path. Poor matching not only reduces heating efficiency but also causes hot spots and uneven heating.

All these design parameters can be screened in a simulation environment. Designing based on numerical evidence reduces the number of prototypes while building a highly reproducible and high-performance reactor.

3. Preventing Microwave Leakage, Arcing/Sparking, and Ensure Compliance with Safety Standards

Since microwave equipment for chemical processes operates at high power, ensuring safety is an absolute requirement. Particularly in industrial applications, microwave leakage and electromagnetic interference (EMI) can affect human health and other equipment, making the pre-assessment of risks and the design of countermeasures using electromagnetic field analysis essential. Furthermore, to prevent equipment damage due to localized heating, it is crucial to design the system to avoid electric field concentrations that could cause arcing or sparking.

- Identification of Potential Leakage Points (Joints, Openings, etc.)

Joints, conveyor openings, and maintenance access points are high-risk areas for microwave leakage. By analyzing the electric field strength distribution, leakage risks can be detected in advance, enabling focused countermeasures.

- Design of Shielding Mechanisms (Comb-Like Structures, λ/4 Chokes, etc.)

It is important to use structural shielding mechanisms to minimize microwave radiation from openings. These mechanisms exhibit resonant reflection and absorption characteristics at specific frequencies, ensuring both functional efficacy and implementation feasibility.

- Design of Shielding Material Placement (Metal Mesh, Carbon Materials, etc.)

For areas that cannot be fully shielded by structural measures, supplementary shielding materials that absorb or reflect electromagnetic waves are used. The shielding effect varies greatly with material properties and placement, so this should also be an analysis target.

- Design to Prevent Arcing and Sparking

Narrow gaps between objects and sharp shapes can cause arcing and sparking. Depending on the size and shape of the equipment, resonance may also cause electric field concentration. A design that avoids these issues is required.

- Compliance Assessment with Safety Standards (JIS C 61000 series, FCC Part 18, EN 55011, etc.)

Meeting these standards is essential for product reliability and market entry. Numerical analysis allows for pre-verification that electric and magnetic fields do not exceed standard limits.

Thus, electromagnetic field analysis is not just a tool for heating design but also the foundation of safety design, and should be actively introduced from the initial stages.

Introduction to Representative Analysis Software (HFSS, CST, COMSOL, etc.)

| Software | Main Method | Features and Strengths |

|---|---|---|

| Ansys HFSS | FEM | High-precision S-parameter analysis. Strong in analyzing resonant structures. |

| CST Studio Suite | FDTD, MoM, etc. | Time-domain and wide-band response. Handles complex conductor structures. |

| COMSOL Multiphysics | FEM + Multiphysics Simulation | Supports integrated analysis of electromagnetic, thermal, fluid, and chemical reactions. Highly versatile. |

| OpenEMS | FDTD | Open-source. Allows for highly flexible analysis design (for advanced users). |

These tools are typically used selectively based on the objective and scale. In recent years, platforms with machine learning integration have emerged, leading to automation and acceleration of design support.

In the design of a microwave reactor, electromagnetic field analysis is the scientific and safety foundation for understanding “where heat is generated, how it propagates, and how it is controlled without leakage.” Unlike conventional chemical equipment design, microwaves are an “invisible heat source,” and their heating principle is complex. This makes it a domain where appropriate design judgments are challenging with prototyping and experiments alone. Therefore, introducing electromagnetic field analysis leads to the realization of efficient, reproducible, and safe microwave equipment. Its use from the initial stages directly contributes to both design quality and development efficiency.

The next chapter will shift the focus to Computational Fluid Dynamics, delving into the challenges of temperature control and reaction field design.

Computational Fluid Dynamics in Microwave Reactor Design

What is Computational Fluid Dynamics (CFD)?

Computational Fluid Dynamics (CFD) is a numerical analysis method that predicts the temperature distribution and fluid motion (gas, liquid, vapor, etc.) within a reactor. In a microwave reactor, it is indispensable for understanding how the heat generated by the electromagnetic field is transported through space and where it accumulates or is cooled.

Notably, microwave heating has a unique mechanism of generating heat internally, unlike external heating. Therefore, it’s not just about heating, but “how that heat spreads and can be controlled” that significantly impacts process performance and safety.

Why Computational Fluid Dynamics is Important in Microwave Reactor Design

1. Prediction of Temperature Distribution

The heat generated by microwaves tends to accumulate unevenly within the sample and equipment, and overheating or uneven heating directly affects the selectivity, yield, and quality stability of the reaction. By using Computational Fluid Dynamics, the following temperature profiles can be visualized:

- Detection of Hot Spots: Predict localized temperature rises to identify risks of thermal degradation or side reactions at the design stage.

- Quantitative Evaluation of Temperature Non-uniformity: Improve heating uniformity by enhancing cooling efficiency or modifying the structure.

- Prediction of Heating Rate: Directly impacts reaction time and start-up control in continuous flow reactors, etc.

This enables the design of a reaction environment with well-controlled temperature.

2. Optimization of Design Utilizing Microwave-Specific Heating Behavior

A significant feature of microwave heating is that it generates heat directly inside the material, rather than applying heat from the outside. This internal heating characteristic presents the following design challenges:

- Internal heating that cannot be fully cooled by convective, radiative, or conductive heat transfer occurs.

- Temperature gradients alter the flow field (thermally induced flow).

- The fluid’s viscosity and density change locally, potentially destabilizing the flow field.

By evaluating these heat-flow interactions (thermal-fluid coupling) through CFD, optimizations such as the following become possible:

- Homogenizing temperature by changing the placement or shape of components.

- Improving temperature controllability by adjusting the flow rate or nozzle position of the cooling medium.

How to Represent Internal Heat Generation from Microwaves

A distinctive feature of CFD for microwave reactors is that the heat source is not applied externally. Instead, the spatial power dissipation density distribution (W/m³) obtained from electromagnetic field analysis is applied internally as the heat source. The general procedure to reflect this is as follows:

- Export the P_abs = ε″E² + μ″H² distribution obtained from electromagnetic field analysis (using software like HFSS or CST) for each spatial grid point.

- Import this distribution into the CFD software and apply it as a heat source.

- If necessary, couple temperature-dependent dielectric properties and thermal properties to build a more realistic simulation.

This method allows for a consistent prediction of the “starting point” of microwave heating and the “result” of the temperature and flow fields it creates. Especially in reactions with strong temperature feedback (e.g., exothermic reactions or those involving condensation/vaporization), the accuracy of this process can determine the success or failure of the process design.

Introduction to Representative Analysis Software (ANSYS Fluent, COMSOL, etc.)

| Software | Main Method | Features and Strengths |

|---|---|---|

| ANSYS Fluent | FVM (Finite Volume Method) | Strong in large-scale, complex thermal-fluid problems. Extensive track record in industrial applications. |

| COMSOL Multiphysics | FEM + Multiphysics Simulation | Excels at integrated analysis of electromagnetic fields, heat, fluid, and reactions. High usability. |

| OpenFOAM | FVM (Highly customizable) | Open-source. Allows for the integration of advanced thermal-fluid models. For advanced users. |

When linking with electromagnetic field analysis results, software with an integrated multiphysics environment, like COMSOL, is advantageous. On the other hand, Fluent is widely adopted for precise fluid control design, and the choice depends on the specific application.

Thus, Computational Fluid Dynamics is a scientific means to determine how to handle the heat generated by microwave heating within the equipment and process. The next chapter will introduce specific Multiphysics Simulation techniques and examples of how combining electromagnetic field analysis and Computational Fluid Dynamics can accelerate design optimization.

Multiphysics Simulation of Electromagnetic Field Analysis and Computational Fluid Dynamics in Microwave Reactor Design

Significance and Benefits of Coupling Electromagnetic Field Analysis and Computational Fluid Dynamics

In a microwave reactor, the electromagnetic field distribution, which is the “origin of heating,” and the temperature/fluid distribution, which is “where the heat is transported,” are closely intertwined. Analyzing them separately can overlook many design challenges, leading to limitations in the consistency of analysis results and the precision of optimization.

This is where the “Multiphysics Simulation” approach becomes crucial. It is a method that numerically connects electromagnetic field analysis (EM) and Computational Fluid Dynamics (CFD), allowing them to proceed while mutually influencing each other.

The Need for Coupling

In microwave heating, the absorption of electromagnetic waves causes the material to heat up, but this temperature rise creates the following “feedback effects”:

- Electromagnetic properties such as permittivity and conductivity change with temperature, altering the absorption efficiency.

- The temperature rise changes the fluid density, causing changes in the flow field (thermally induced flow).

- The location of absorption and hot spots varies over time.

These phenomena form a feedback loop: electromagnetic field → temperature → electromagnetic field…, which can only be accurately evaluated through Multiphysics Simulation.

Key Benefits

- Enables design that reflects the time-dependent changes in heating behavior.

→ Provides a realistic response that includes the temperature-dependent properties of the sample.

- Improves the accuracy of risk assessment for uneven heating and thermal runaway.

→ Allows prediction of cascading overheating and hot spot migration.

- Allows for the simultaneous optimization of heating and cooling performance.

→ Enables a well-balanced design for the entire reaction space.

Multiphysics Simulation is not merely a means to improve analysis accuracy; it is a strategic tool for designing more stable and high-performance reactors while reducing development time and prototyping costs.

Challenges and Solutions in Microwave Reactor Design

Cause Analysis and Countermeasures When Experimental Data and Simulation Results Do Not Match

While Electromagnetic Field Analysis and Computational Fluid Dynamics are powerful tools for microwave reactor design, a common challenge in practice is that the heating behavior and temperature distribution in the actual equipment do not match the simulation results. Below are the main causes and their countermeasures.

| Main Cause | Description | Example Countermeasure |

|---|---|---|

| Inaccuracies in Material Properties | Discrepancies between the simulation’s properties (e.g., permittivity, thermal conductivity, viscosity) and their actual values. | Develop a material property database for different sample temperatures / Conduct permittivity measurements. |

| Incorrect Boundary Conditions | Ambiguity in input power, heat transfer coefficients, or heat dissipation conditions. | Sequentially update based on feedback from experimental data. |

| Over-simplification of the Model | Excessive simplification of geometry or fluid behavior. | Use local mesh refinement to introduce detailed models only for critical parts. |

| Mismatch between Measurement and Analysis Points | Comparing point temperatures from experiments with average values from analysis. | Reconfirm measurement locations and methods, and synchronize them with analysis points. |

To achieve high-precision analysis, a development system that can rapidly iterate through the loop of analysis—prototyping—re-analysis is crucial.

Experimental Approaches for Validating Electromagnetic Field Analysis and Computational Fluid Dynamics

To effectively use simulation results in practice, their validity must be confirmed (validation). Below are representative experimental approaches.

- Three-dimensional Temperature Distribution Measurement with Fiber Optic Temperature Sensors

→ Directly measure the temperature inside the reactor using sensors that can operate in high-temperature and high-electromagnetic-field environments.

- Thermal Imaging (IR Camera) with Anti-reflection Windows

→ Acquire time-series temperature changes from outside the reactor through a transparent window.

- S-parameter Measurement with a Network Analyzer

→ Measure the reflection coefficient (S₁₁) of the actual equipment to evaluate matching and absorption efficiency.

- Permittivity Measurement (including temperature dependence) → Obtain material properties at high temperatures using a setup that combines a cavity resonator with a high-temperature furnace.

Through these experiments, it becomes possible to progressively verify “how well the numerical model reproduces reality” and enhance the reliability of the design.

Latest Trends in Simulation Technology for Microwave Reactor Design

Examples of Improving Efficiency and Accuracy in Electromagnetic and Computational Fluid Dynamics Using AI and Machine Learning

Traditionally, Multiphysics Simulation of electromagnetic and thermal-fluid fields required high expertise and extensive computational time. However, the introduction of AI technology has brought about the following changes:

- High-speed prediction of design parameters and absorption distribution using regression models

→ By training on multiple sample placement and shape patterns, microwave heating distribution can be predicted in milliseconds.

- Automated design of feed structures using Bayesian optimization

→ AI proposes structures that maximize absorption efficiency, using microwave simulation results as training data.

- Risk detection of temperature non-uniformity using deep learning

→ “Dangerous localized overheating patterns” are extracted from temperature distribution data and used for anomaly prediction.

By using AI, design iterations that previously took dozens of hours can now be completed in minutes or even seconds, contributing to both the speed and quality of process development.

Utilization of Cloud-based Simulation (Scalability and Acceleration)

The emergence of cloud platforms has made high-performance computing environments available on a subscription basis, offering the following benefits:

- Simultaneous execution of large-scale parameter sweeps (e.g., parallel validation of 100 different feed angles or vessel materials).

- Analysis with high-resolution meshes, independent of local PC performance.

- Easy file sharing and team-based collaborative design (particularly effective in joint development with equipment manufacturers).

Representative cloud-based analysis services include Ansys Cloud, SimScale, and COMSOL Cloud. They are gaining attention as a means to ensure the “immediacy” and “high number of trials” in the design phase.

Latest Trends in Real-time Simulation and Digital Twin Technology

In recent years, the ” digital twin,” which integrates physical models with real-world machine data, has begun to be applied to microwave equipment.

- Real-time estimation and control of absorption and temperature distribution.

- Visualization of reactor state changes and feedback to the control system.

- Realization of “model-based prediction” for maintenance and anomaly diagnosis.

For example, by incorporating real-time measurements from temperature and power sensors into a coupled electromagnetic and thermal-fluid model, technology is nearing practical use that reconstructs the current internal state of the equipment in real time and assists in optimizing operating conditions.

Such initiatives hold the potential to evolve microwave equipment from “black boxes” into “intelligent systems capable of feedback.”

Conclusion

In the design of a microwave reactor, Electromagnetic Field Analysis, Computational Fluid Dynamics, and Multiphysics Simulation represent a domain that demands entirely different concepts and tools compared to conventional equipment design. Microwaves are an “invisible heat source,” and understanding how electromagnetic energy is distributed in time and space and how it propagates as temperature and flow requires scientifically-backed numerical analysis.

As discussed in this article:

- Electromagnetic Field Analysis addresses the origin of heating.

- Computational Fluid Dynamics addresses the spread and control of heat.

- Multiphysics Simulation enables the optimization of the entire design.

Furthermore, technologies such as AI, the cloud, and real-time simulation are being introduced into this field, leading to remarkable progress in acceleration, automation, and predictive accuracy.

Microwave technology is moving beyond being just a heating method into an era of dynamically designing the reaction field itself. For this, traditional design approaches are insufficient, and an integrated design of electromagnetic fields, heat, and fluids will be essential for future development.

At Microwave Chemical Co.,Ltd, we leverage these advanced simulation technologies to strongly support our clients’ microwave process development. Please feel free to contact us for more details.

References

[1] Rana, K. K., & Rana, S. (2016). Microwave Reactors: A Brief Review on Its Fundamental Aspects. Open Access Library Journal, 3, e64319.

[2] Sun, J., Wang, W., & Yue, Q. (2016). Review on Microwave-Matter Interaction Fundamentals and Efficient Microwave-Associated Heating Strategies. Materials, 9(4), 231.

[3] Dąbrowska, S., Chudoba, T., Wojnarowicz, J. & Łojkowski, W. (2018). Current Trends in the Development of Microwave Reactors for the Synthesis of Nanomaterials in Laboratories and Industries: A Review. Crystals, 8(10), 379.