Microwave Energy Transfer: Principles, Applications, and Optimization

What is Microwave Heating?

In recent years, microwave heating technology has garnered attention as a novel solution to replace conventional thermal processing technologies, owing to its unique heating mechanism and high energy efficiency. Microwave energy is supplied directly into the interior of the object being heated, a clear departure from traditional methods that rely on thermal conduction or convection. This article provides a systematic explanation of this technology, from its fundamental principles to industrial applications and future prospects, focusing on keywords such as “microwave heat,” “microwave heat transfer,” “microwave energy transfer,” and “microwave irradiation.”

Microwave heating is a method that generates heat by irradiating a substance with microwaves in ISM bands (specific frequency bands for industrial, scientific, and medical use), such as 915 MHz, 2.45 GHz, and 5.8 GHz. This process causes polar molecules (a typical example being water) within the substance to vibrate and rotate. Unlike heating from an external source like an oven or heater, this is characterized as “volumetric heating,” a unique feature of this technology.

How Microwaves Generate Heat

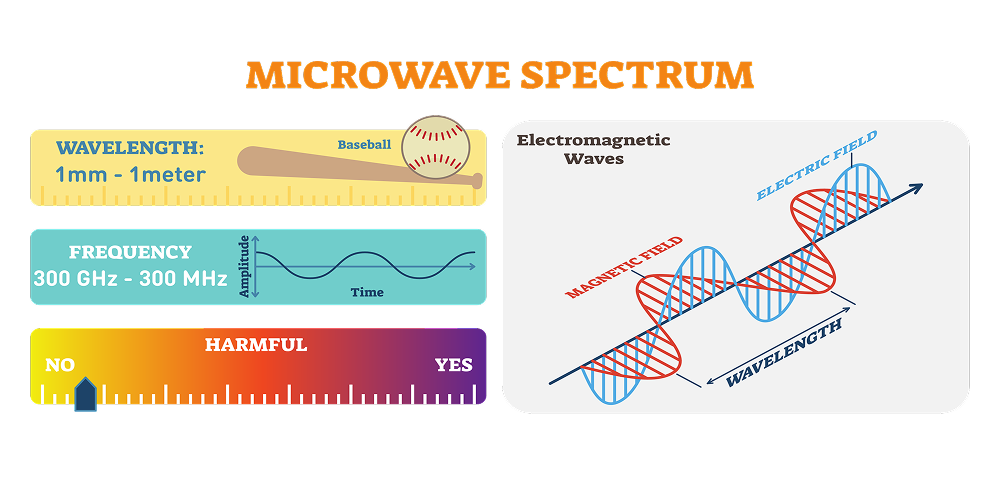

Microwaves are a type of electromagnetic wave, and their energy originates from the periodic fluctuations of electric and magnetic fields. Polar molecules within a substance (e.g., water molecules) rapidly change their orientation in response to these changing electric fields, creating friction and consequently generating heat. This is the principle of “dielectric heating.” [1] Furthermore, in conductive materials, microwaves induce the movement of electrons and ions, causing “conduction heating” to occur simultaneously. These mechanisms enable heating from within, which differs from conventional surface heating.

The Science of Microwave Energy Transfer

Microwave energy transfer is fundamentally different from traditional thermal conduction (between solids) or convection (between fluids); it directly utilizes the thermal response within the material itself. Microwaves do not uniformly penetrate an object. Instead, the energy distribution is determined by factors such as the material’s complex permittivity (a physical property representing its response to microwaves), as well as its shape and size.[2]

Mechanisms of Microwave Energy Transfer

Microwave heating warms substances from the inside through two primary mechanisms: dielectric heating and Joule heating.

1. Dielectric Heating

- Vibration and Rotation of Polar Molecules: Polar molecules, such as water, have a natural electrical imbalance (positive and negative poles). Microwaves force these molecules to rapidly reorient themselves, causing friction and collisions at the molecular level.

- Heat Generation: This intense molecular movement is converted into thermal energy, allowing the entire substance to heat up. Because it does not require waiting for heat to transfer from an external source, this process is also known as volumetric heating, enabling rapid and uniform heating.

2. Joule Heating

- Movement of Ions and Electrons: When microwaves are applied to a conductive substance (like an electrolyte solution), the ions and electrons within are accelerated by the microwave’s electric field.

- Heat Generation: As these particles collide within the substance, Joule heat is generated, warming the material.

Through the combined action of these mechanisms, microwaves efficiently transfer energy from within a substance, achieving uniform heating in a short amount of time. It should be noted that for some magnetic materials, magnetic losses caused by the microwave’s magnetic field also contribute to heating. Still, dielectric and Joule heating are the central principles in a general explanation.

Factors Affecting Microwave Energy Transfer

The following factors significantly influence the efficiency and uniformity of microwave heating:

- Dielectric Properties of the Material: Permittivity and dielectric loss factor.

- Moisture Content: Higher water content generally leads to higher heating efficiency.

- Temperature Dependence: The dielectric properties can change as the material heats up, which may alter the heating pattern.

- Frequency and Power: Adjusting irradiation conditions can optimize heating depth and speed.

Particularly in reaction systems or complex mixtures, the properties of the materials change as heating progresses, necessitating real-time monitoring and feedback control.

Application Fields of Microwave Irradiation

Industrial Applications

Microwave heating is being actively adopted in the following industries:

- Food Processing: Dehydration, sterilization, thawing, and drying (e.g., high-efficiency vegetable drying lines) [3].

- Pharmaceuticals: Reaction promotion, crystallization, and manufacturing of high-purity formulations through uniform heating.

- Chemical Processes: Acceleration of catalytic reactions, reduction of reaction times, and improvement of selectivity (e.g., fatty acid esterification, conversion of aromatic compounds) [4].

- Electronic Materials: Sintering of ceramics and processing of carbon materials like CNTs (Carbon Nanotubes) [5].

Microwave Chemical Co., Ltd. has a proven track record in scale-up, with practical-scale microwave reactor units, continuous calcination lines, and batch-type pharmaceutical intermediate synthesis equipment already operating in the industry field.

Use in Medical and Scientific Fields

In the medical field, microwave applications are rapidly expanding:

- Microwave Ablation (MWA): A minimally invasive treatment that uses high frequencies around 2.45 GHz to thermally coagulate and necrotize tumors, such as hepatocellular carcinoma [6]. Compared to conventional radiofrequency ablation (RFA), MWA creates a more spherical ablation zone, improving treatment precision.

- Vascular Occlusion Therapy: Treatment of lesions through localized heating [7].

- Materials Science: Rapid synthesis of high-performance materials, surface modification of nanoparticles, and catalyst development [8].

In research, studies are advancing on the unique aspects of microwave reactions (e.g., non-thermal effects, selective activation states) for novel catalyst design and process intensification.

Optimization of Microwave Heating

Optimizing Heating Time for Different Materials

In microwave heating, it is crucial to control the heating time based on the dielectric properties of each material.

For instance, foods with high moisture content heat up rapidly due to high dielectric loss. However, the surface can overheat before the interior, leading to quality degradation and loss of flavor. In such cases, methods like pulse irradiation (intermittent heating) or physically moving the target object can mitigate temperature gradients and achieve uniform heating.

On the other hand, in solid-state reactions involving inorganic materials, the dielectric properties are known to change as the reaction progresses. Therefore, the heating conditions must be dynamically adjusted accordingly. For processes like ceramics sintering or ore reduction, real-time dielectric property tracking technology and power control based on the degree of reaction progress are particularly important.

At Microwave Chemical Co., Ltd., we are advancing the automation of heating time and power adjustments by incorporating real-time temperature sensing and monitoring with thermal cameras.

Energy Efficiency and Sustainability

Compared to conventional heating, microwave heating offers the following environmental advantages:

- Efficient Use of Heat: Energy is supplied directly to the interior of the target, allowing for its effective use without unnecessarily heating surrounding structures or media.

- Selective Heating: The heating behavior can be controlled based on the material’s dielectric properties, making it possible to heat only specific components or optimize the temperature distribution of the reaction field.

- Reduced Reaction Time and CO₂ Emissions: The rapid heating response leads to shorter overall process times, which indirectly suppresses energy consumption and CO₂ emissions.

- Potential for Smaller Equipment: The integration of the heating source and simplification of insulation design can, in some cases, lead to more compact, space-saving equipment.

It is worth noting that in typical industrial microwave equipment using magnetrons or solid-state oscillators, the conversion efficiency from electricity to microwaves is generally around 50-85%. Furthermore, the efficiency with which the target absorbs microwaves depends on the material and its shape. Therefore, while the conversion efficiency itself is not exceptionally high, microwave heating is gaining attention for its high efficiency in the application of heat, especially in fields where conventional heating methods tend to have low thermal efficiency.

Microwave Chemical Co., Ltd. is leveraging these characteristics to promote “Carbon-Neutral Heating Solutions” for a decarbonized society.

Challenges and Future Outlook

Challenges of Microwave Heating

The main challenges currently facing microwave technology include:

- Uneven Heating (Hotspots): Localized heating caused by microwave interference.

- Difficulty in Heating Metallic Materials: Risk of reflection and arcing.

- Equipment Cost: Costs associated with high-power magnetrons and power supply systems.

- Difficulty of Scale-Up Simulation: Numerical analysis and optimization design requires significant time. A robust microwave simulator is essential to overcome this hurdle.

Innovations in Microwave Energy Transfer Technology

To address these challenges, the following technological innovations are underway:

- Optimal geometry design using high-precision coupled analysis of electromagnetic fields and thermo-fluid dynamics.

- Utilization of solid-state dielectric antennas (e.g., patch antennas).

- Dynamic feedback using Automatic Frequency Control (AFC) magnetrons.

- Modularization and distributed heating designs for the microwave reactor.

In the future, it is predicted that technology is expected to become more intelligent and efficient, incorporating advancements like AI-driven control of heating profiles [9].

These challenges and their technical backgrounds are discussed in detail in a separate article: “Numerical Simulation Technology for Microwave Reactor Design: Practical Applications and Latest Trends in Electromagnetic, Thermo-fluid, and Coupled Analysis.“

Conclusion

Microwave heating has evolved far beyond simple microwave oven technology. It is now positioned as a “selective, rapid, and sustainable heating technology” that is bringing innovation to all fields, including industry, medicine, and research. Its high energy transfer efficiency and equipment flexibility are directly linked to the future realization of distributed manufacturing and a decarbonized society.

At Microwave Chemical Co., Ltd., we have established an end-to-end partnership framework that accompanies our clients from design and testing to practical implementation and scale-up, and we remain committed to pioneering the future of thermal energy utilization.

References

[1] Grant, E. H., & Halstead, B. S. J. (1998). Dielectric parameters relevant to microwave dielectric heating. Chemical Society Reviews, 27(4), 213-223.

[2] Santos, T., Valente, M. A., Monteiro, J., Sousa, J., & Morais, L. (2011). Electromagnetic and thermal history during microwave heating. Applied Thermal Engineering, 31(16), 3255-3261.

[3] Chandrasekaran, S., Ramanathan, S., & Basak, T. (2013). Microwave food processing—A review. Food Research International, 52(1), 243-261.

[4] Hayes, B. L. (2004). Recent advances in microwave-assisted synthesis. Aldrichimica Acta, 37(2), 66-76.

[5] Menéndez, J. A., Arenillas, A., Fidalgo, B., Fernández, Y., Zubizarreta, L., Calvo, E. G., & Bermúdez, J. M. (2010). Microwave heating processes involving carbon materials. Fuel Processing Technology, 91(1), 1-8.

[6] Simon, C. J., Dupuy, D. E., & Mayo-Smith, W. W. (2005). Microwave ablation: principles and applications. Radiographics, 25(suppl_1), S69-S83.

[7] Chiang, J., Cristescu, M., Lee, M. H., Moreland, A., Hinshaw, J. L., & Lee, F. T. (2016). Effects of microwave ablation on arterial and venous vasculature after treatment of hepatocellular carcinoma. Radiology, 281(2), 611-618.

[8] Dahal, N., García, S., Zhou, J., & Humphrey, S. M. (2012). Beneficial effects of microwave-assisted heating versus conventional heating in noble metal nanoparticle synthesis. ACS Nano, 6(11), 9433-9446.

[9] Yao, Q., Zheng, X., Wang, R., Liang, W., Liu, T., & Chu, W. (2024). Control of thermal uniformity in microwave heating process by BPNN and adaptive particle swarm optimization. Heliyon, 10(17), e37971.