Service & Technology

Controlling microwaves

Our operation systems are designed to safely manage and control microwave irradiation.

One feature of microwave irradiation is that the target substance can be heated internally rapidly and selectively than conventional methods that use conduction or radiant heat. Therefore, controlling the microwaves is crucial to achieving appropriate heating.

We grasp the difference between incident and reflected electricity to assess the level of microwave irradiation, monitor in real-time whether the irradiation level is appropriate in relation to temperature changes in the heated object. By providing the feed-back to the microwave irradiation method, we are developing a system which maintains adequate level of irradiation as well as detecting errors for commercial use.

Safety system

We carefully consider microwave leakage in all our designs to ensure the safe usage of the microwaves. The internal standards we have created allow us to develop designs that prevent microwave leakage, build systems to detect any microwave leakage, and incorporate emergency shutdown systems.

-

Leakage prevention system

To prevent microwave leakage, we design nozzle lengths, gaps between flanges and stirring shafts, stealing materials and the like by combining analysis of electric field simulations with our vast experience.

-

Leakage detection and emergency shut down system

The detection devices inside the safety system will shut down the microwave power source in the unlikely event of a leakage. Additionally, any abnormalities attributable to microwaves (local temperature anomalies, sparking, etc.) are kept inside the microwave control system interlocks to further increase safety.

-

Internal standards

Japan’s official EMF Protection Guidelines (Denpa Bōgo Shishin) stipulates the permissible impact of the microwaves on the human body. To ensure that microwave radiation does not cause transmission failures, etc. in nearby equipment, we created our own leakage prevention standards that satisfy international guidelines (ANSI-IEEE & ICNIRP) and the guaranteed performance during operation. The standard allows us to operate our reactor with hazardous materials as defined in the Fire Service Act and ensure that our design complies with relevant legislation such as the Industrial Safety and Health Act, the High-Pressure Gas Safety Act, and the Radio Act.

Controlling electric fields (phased control)

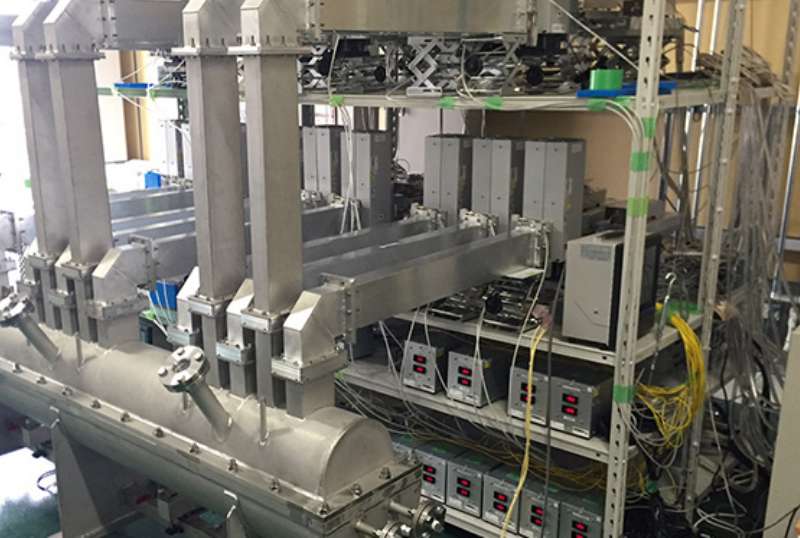

Microwave spatial synthesis using semiconductor (GaN) microwave oscillator No. 15

We can control the phase of the microwaves which allows even more effective use.

For example, if multiple oscillators are aimed at a target substance within a reactor and the phases of the microwaves are controlled and aligned, we can focus energy transmission to a target location in a reactor. This way, the energy transmission will be more localized and as a result it becomes more efficient.

We can also build reactors that transmit energy with high efficiency, by deploying sensors to gather information from within the reactor, and a microwave control unit which feeds back the oscillation frequency to the reactors.

Controlling the phase of the microwaves allows us for the stable, safe, and efficient transmission of the energy.

We have patented the above methods for the effective transmission of energy using microwaves under Japanese patent nos. 6261789, 610994, and 6088690.